Polypropylene lined hose with galvanized steel inner and outer wires designed specifically for Bottom Loading applications where a high degree of reliability is required with media charged into the hose 24/7.

When calculating the length it is important to note if length is either pressurized (“wet”) or empty (“dry”) as the effect of elongation must be calculated in order to produce the correctly manufactured length. Hose is full conductive, typically less than 10 ohms. All hose assemblies are pressured tested 100% to 1-1/2 times MAWP and are available with steel or aluminum TTMA flanges, fixed or floating, elbows, threaded connections or couplers. Working pressures of up to 250 psi (17 bar) with conformance to EN 13765:2010 and working temperatures of up to 100 degrees C (212 F).

Oilmaster® Bottom Loading Hose Type GGB901

This type is designed exclusively for the bottom loading arm application for filling tank trucks suitable for all grades and blends of refined gasoline products with unique fiberglass flame resistant layer.

Color/Cover: Black with a Blue and White Stripe/PVC Coated Nylon, Abrasion, UV and Ozone Resistant

Inner Wire: Galvanized Steel

Inner Lining: High Density Polypropylene

Carcass: Fiberglass Flame-Resistant Layer, Polypropylene Fabrics and Nylon Films

Outer Wire: Galvanized Steel

Temperature Range: -22°F to +212°F (-30°C to +100°C)

Maximum Elongation: ≤10% on test pressure

Vacuum Range: 26 inHg (660 mmHg), 0.9 bar

Electrical Properties: Electrically Conductive; ≤1.0 ohm/m

BS5842, NAHAD-600:2005

Specially designed end fittings have been developed for use with Titeflex US Hose composite hoses that have a unique leak-proof sealing face and specially machined helical spiral shank which engages into the corresponding internal helix wire when secured into the hose by either crimping or swaging the external ferrules.

For GGB90l Bottom Loading Hose measure the lengths as either “pressurized” or “empty”. The effect of elongation must be calculated in order to produce the correctly manufactured length and price.

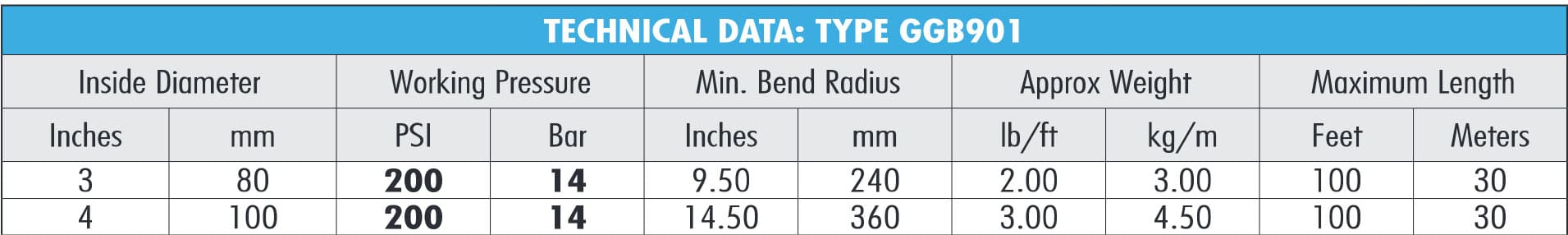

Pressure based on safety factor 4:1. Dimensions and weight are approximate and are subject to change. For additional technical data such as pressure drop, max. flow rates and tensile strength, please consult Titeflex US Hose engineering. Increased operating temperatures will reduce working pressure of the assemblies. Fitting pressure rating may limit working pressure of the assembly. Rated working pressure is @ 70°F (21°C).