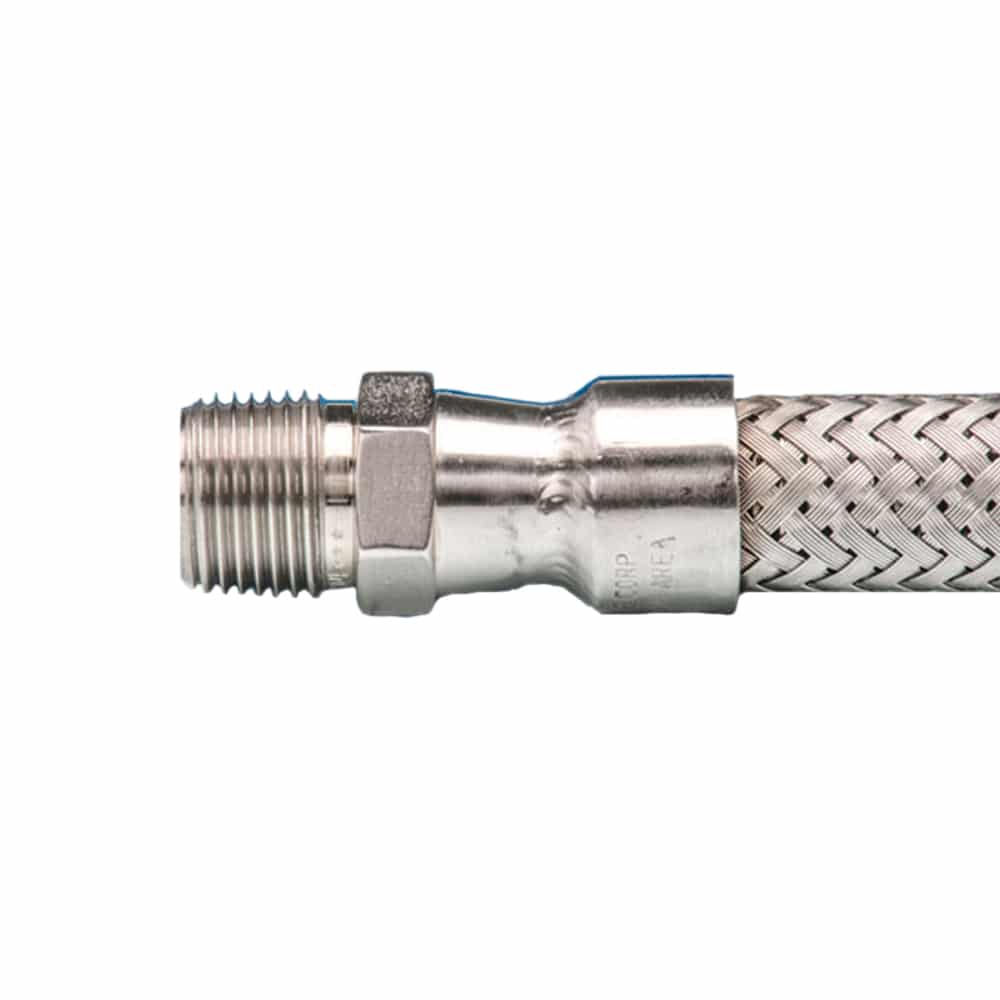

Metal Braided Hoses and Hose Assemblies

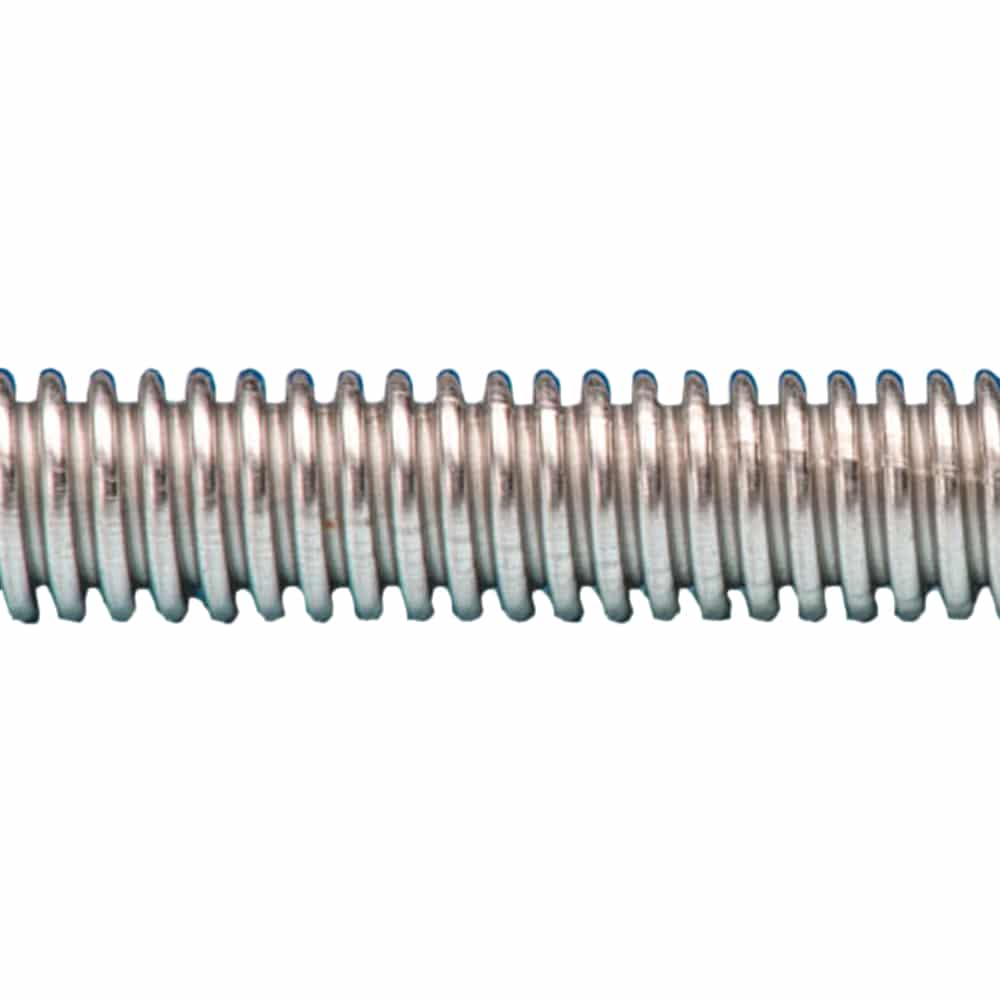

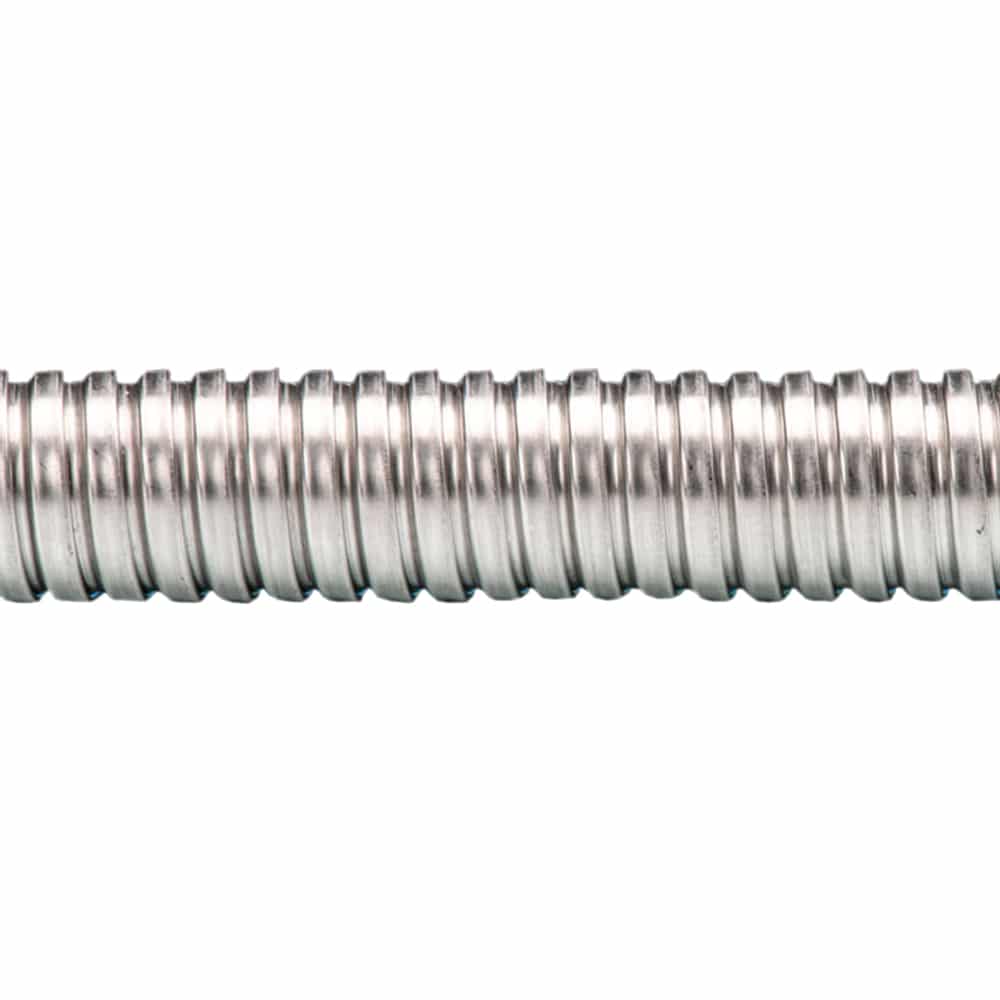

Titeflex US Hose is a leader in metal braided hose assemblies with a heritage dating back over 100 years. Our global facilities offer a broad range of corrugated inner core diameters and designs, multi braiding capabilities, and engineered assembly expertise to meet applications sub-sea, on land or in outer space. United Flexible offers corrugated hose with a self-draining helical design, or a more robust and flexible annular design, available with a ¼” diameter (6mm) and larger.

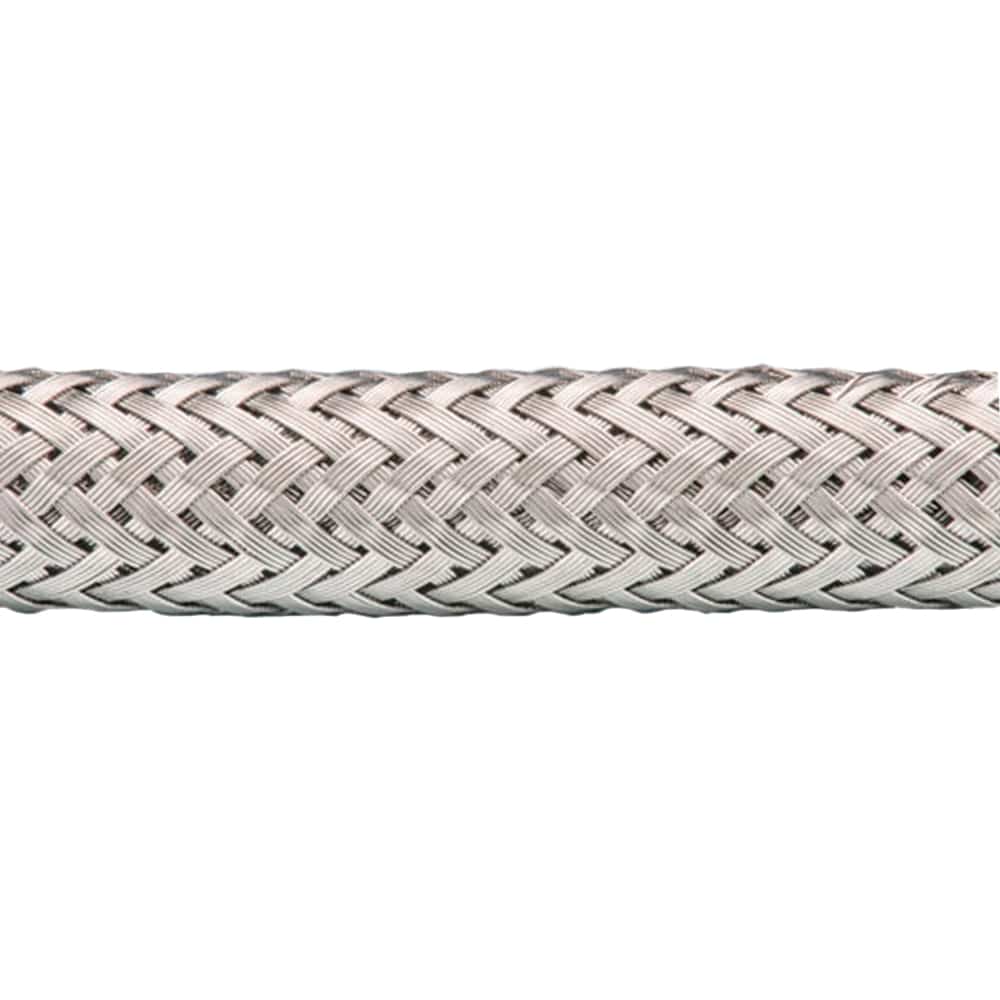

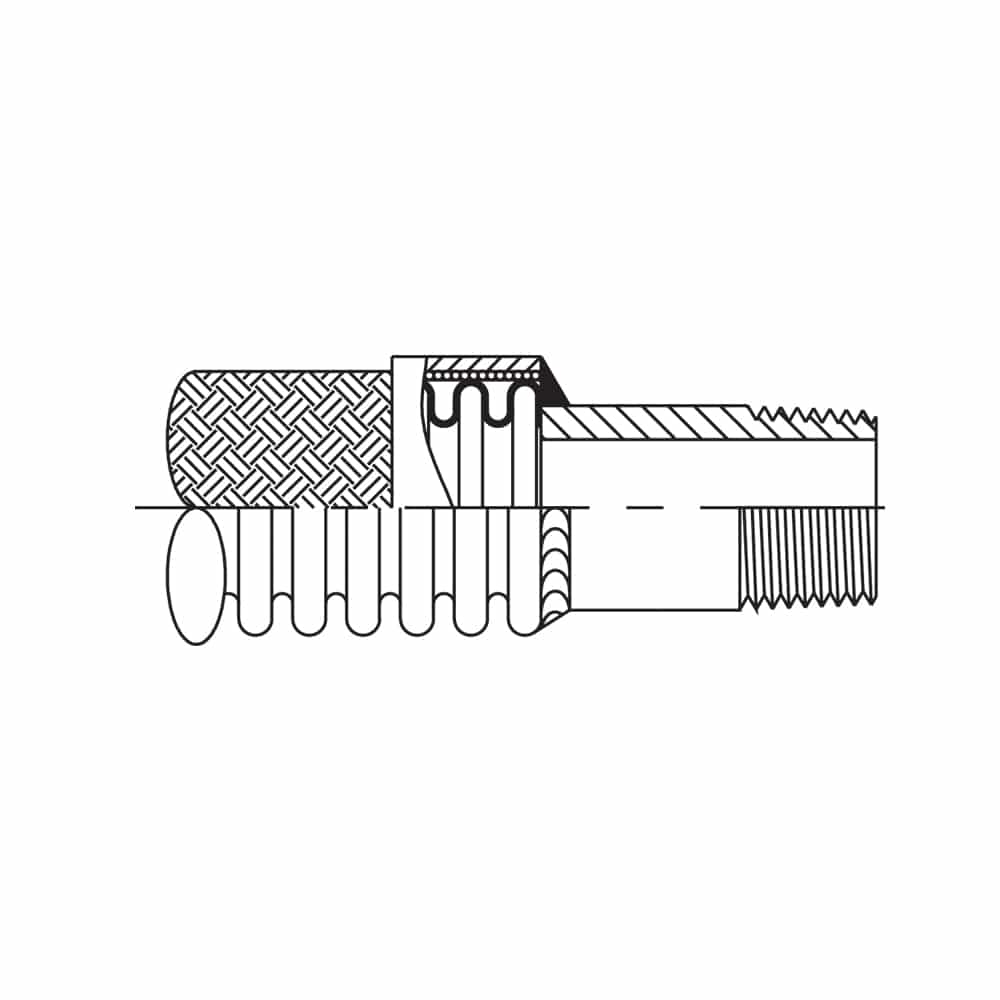

These metallic hoses are braided to give strength when the hose is pressurized and to provide a solid protective cover during use. Typical materials such as 316L and 321 stainless steel can withstand extreme variations in temperature, from cryogenic up to 1500°F (815°C). Multiple braid layers can increase working pressure as well as with corrugation shape, profile, wall thickness and material type. With differing engineering techniques involved and excellent burst strength-to-wall thickness ratio, these hoses are relatively lightweight compared to equivalent non-metallic hose alternatives in the market.

Download CatalogCERTIFIED PROCESSES

United Flexible’s metallic hose manufacturing operations offer ISO 9001:2015 and AS9100:D certified processes and procedures. Some metallic hoses are engineered and designed to ISO 10380 while others conform to the design codes of EJMA and ASME Section VIII that meet the requirements of the boiler, pressure and piping codes of B31.1 and B31.3. Our global workforce of welders are ASME IX certified.