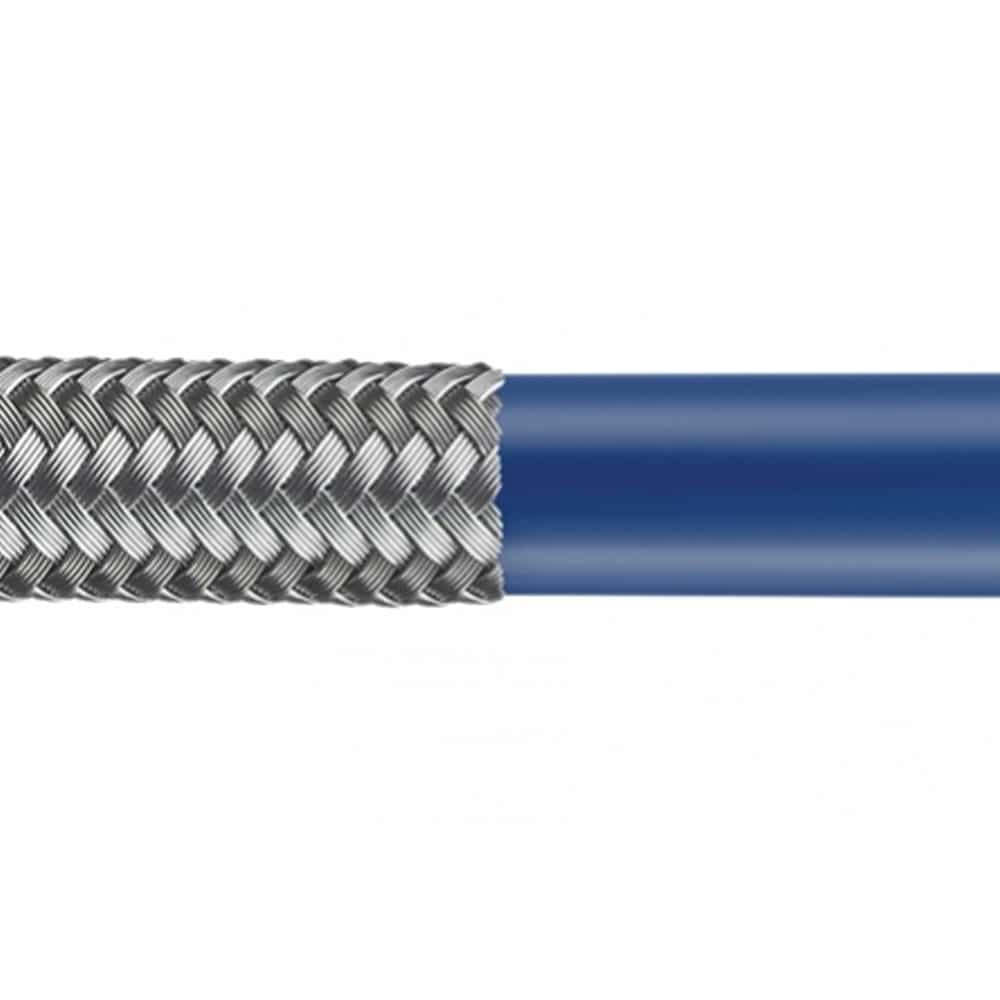

Titeflex R122/R144 PTFE hose contains innercore which has been extruded vertically to maintain the highest quality of concentricity.

Titeflex R122/R144 hose PTFE innercore has a wall thickness of 0.030″. Titeflex PTFE is manufactured from Dupont type 62 fine grade resin or equivalent and uses 304 stainless steel wire braid as reinforcement. Additionally a precisely controlled amount of carbon black added to the PTFE innercore provides a continuous conductive path to the metal end fittings, to bleed off static electricity in steam or high flow-rate applications. Titeflex R122/R144 Series hose sizes -4 through -10 are rated for full vacuum. Larger sizes -12 and above can be reinforced with an internal support spring for full vacuum service. Titeflex R122/R144 Series hose has an operating temperature range of -65°F to +400°F (-54°C to +204°C) for continuous service or -100°F to +500°F (-73°C to +260°C) for intermittent service.

Titeflex R122/R144 Series

Hose Construction

- Innercore vertically extruded to maintain highest quality of concentricity

- Manufactured from fine powder PTFE

- 304 stainless steel wire braid reinforcement

- The R122/R144 Conductive Hose has precisely controlled amount of carbon black added to the PTFE innercore provides a continuous conductive path to the metal end fitting, to dissipate static electricity in fuel, steam, or high flow-rate applications

Standards

- Meets or exceeds requirements of SAE 100R14

- PTFE meets FDA 21 CFR 177.1550

Vacuum Service

- Sizes -4 through -10 are rated for full vacuum

- Larger sizes -12 and above can be reinforced with an internal support spring for full vacuum service

WARNING: This product can expose you to chemicals including Tetrafluoroethylene which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

- Compressed gas

- Fuel and lubricant handling

- Steam transfer

- Hydraulic systems

- No Phthalate. Titeflex only uses 100% PTFE, and conductive PTFE in the liner that remains flexible and does not leach.

- Design optimized for your specific application.

- Manufactured in long lengths to reduce hose costs associated with coupling hose sections.

- Economical and cost effective.

- Innovative PTFE technology by Titeflex satisfies the demanding aerospace, automotive, and industrial applications. The driving force is Titeflex commitment to safety, quality, value, and reliability. Modern quality production and customer satisfaction make Titeflex the leading PTFE hose producer.

- -65°F to 400°F (-54°C to 204°C) for continuous service

- -100°F to 500°F (-73°C to 260°C) for intermittent service

Consult factory for temperature adjusted pressure rating.

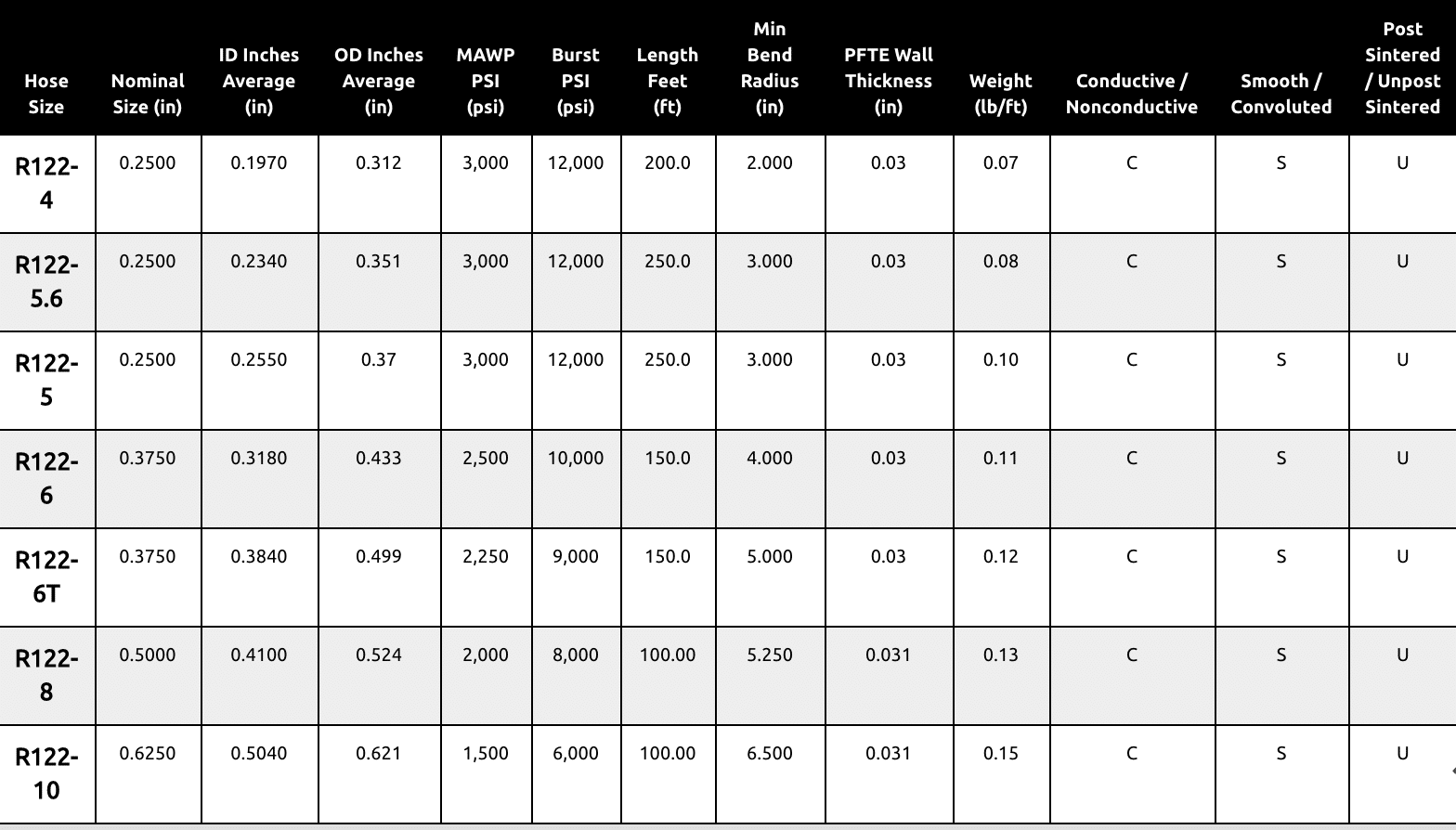

Imperial

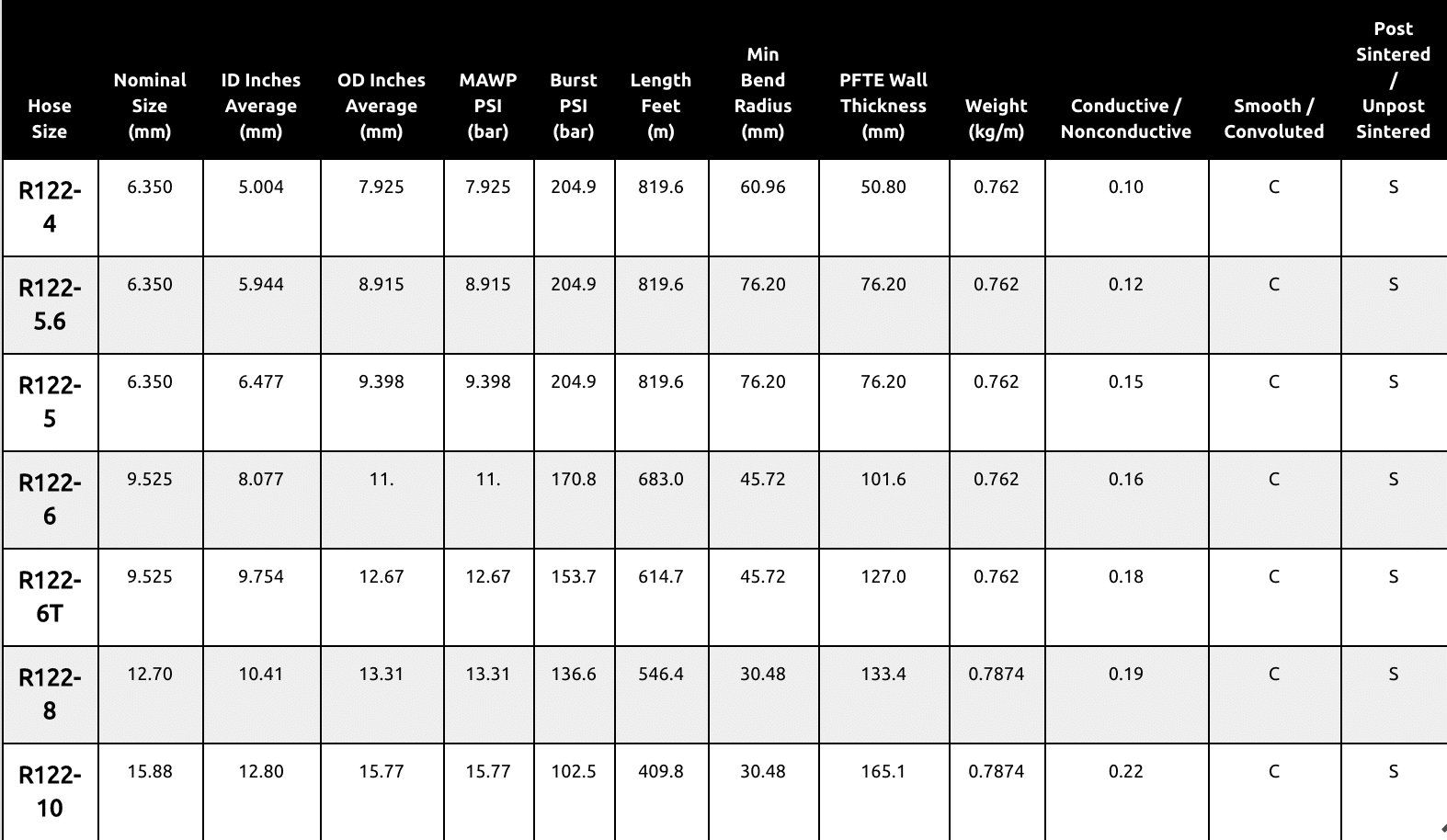

Metric

DISCLAIMER: While every effort has been made to present the latest technically accurate information, industry standards and specifications are subject to revision at any time and human errors can occur. The products and designs offered herein, without limitation, are subject to change at any time without notice. Improper selection or use of products offered herein can result in injury or death.