Titeflex R160/R165 series…The original UNI-BRAID® design that outperforms all the others.

UNI-BRAID® high-pressure hose is the most economical high pressure PTFE hose product ever offered to the market. It combines long life expectancy, high durability, and proven performance for superior service and cost effectiveness over the long term.

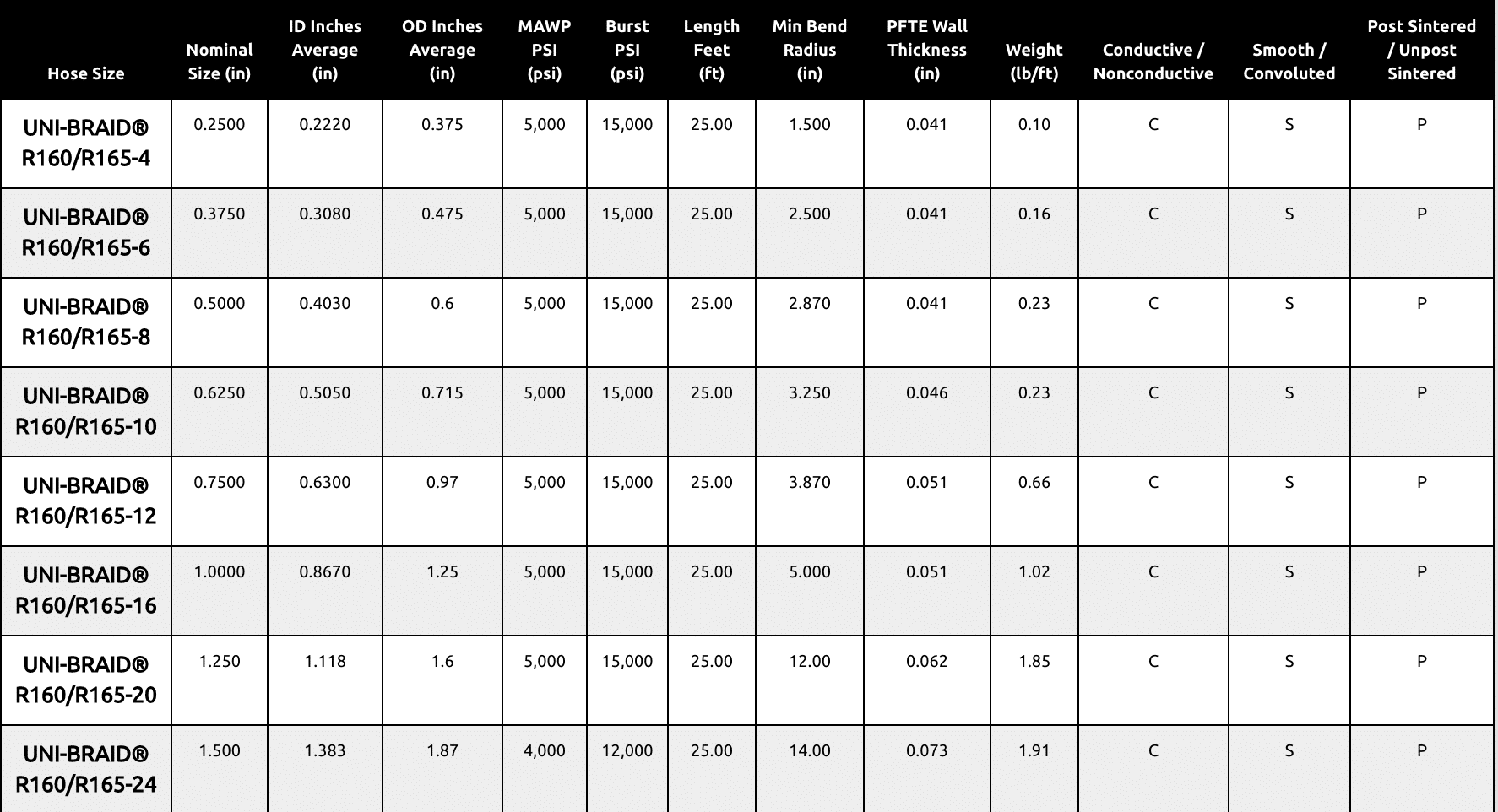

UNI-BRAID® R160/R165 Series

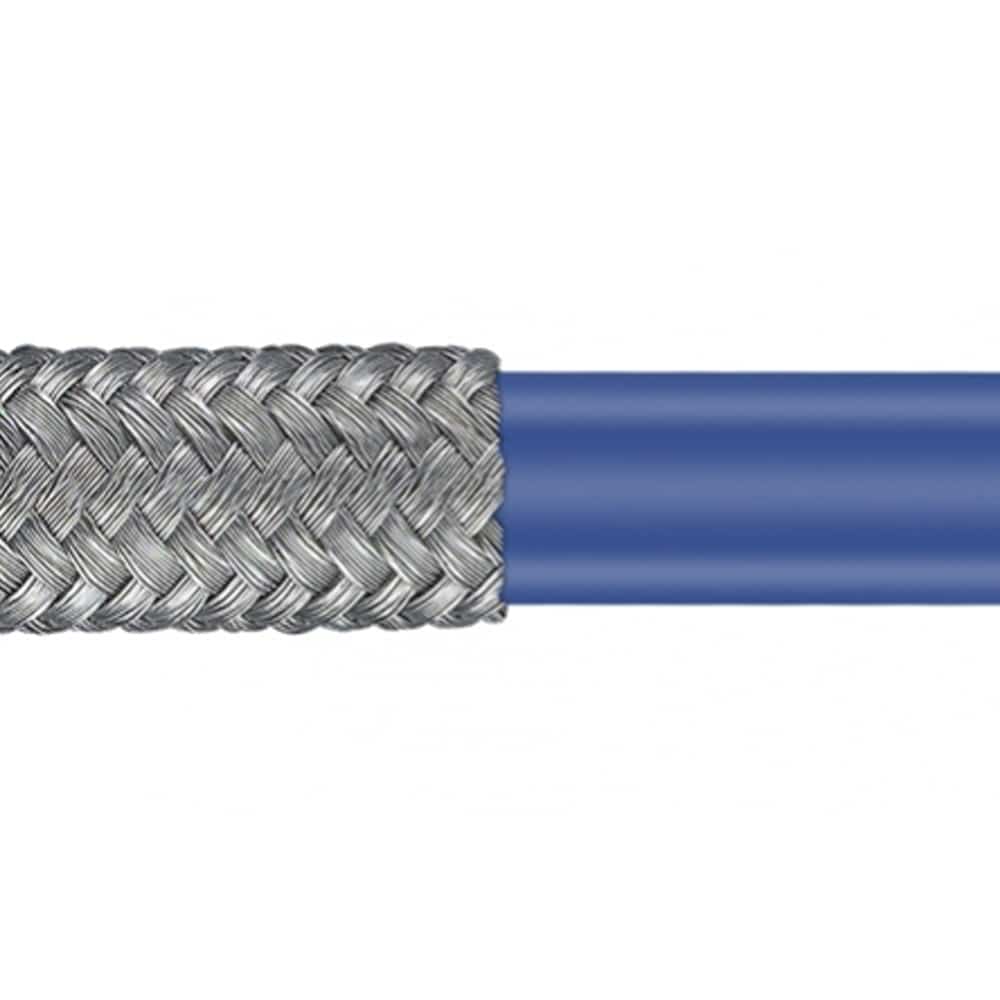

Hose Construction

- R160/R165 hose is made of conductive PTFE using Titeflex “ZS”(Zero Static) construction, to bleed off static build-up in high flow applications and eliminate the risk of “static” burning of the core.

- This specially designed braid eliminates conventional spiral wraps, reducing weight and bulk without sacrifice of pressure capability.

- In larger sizes (-12 thru -24) there is an additional braid layer between the PTFE innercore and the pressure carrying outer braid.

- R160 hose’s innercore is thermally treated to enhance hose performance in extreme applications.

Availability

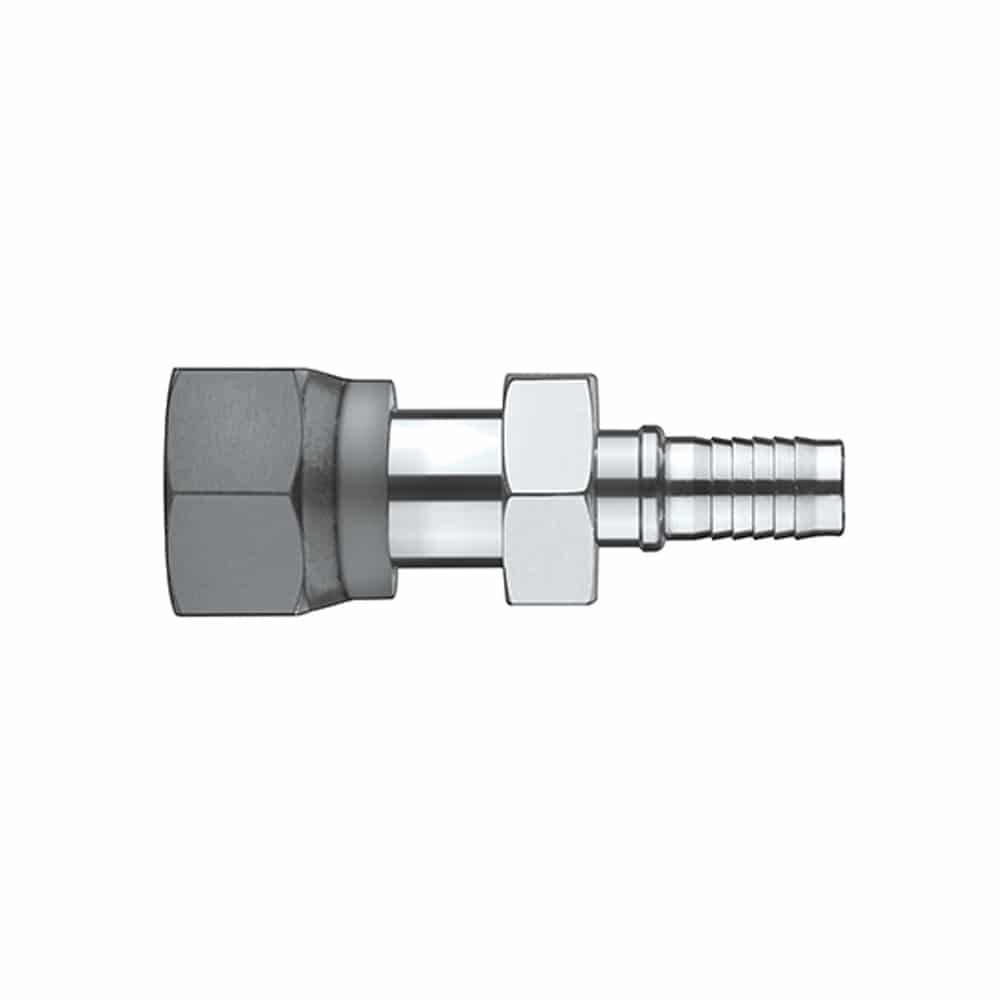

UNI-BRAID® can be fitted and tested to your exact specification by Titeflex or by an authorized Titeflex distributor. Our distributors are selectively certified to assemble high pressure hose assemblies. Insist that your Titeflex product is assembled and supplied by a Titeflex authorized distributor.

WARNING: This product can expose you to chemicals including Tetrafluoroethylene which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

- No Phthalate. Titeflex only uses 100% PTFE, and conductive PTFE in the liner that remains flexible and does not leach.

- Design optimized for your specific application.

- Manufactured in long lengths to reduce hose costs associated with coupling hose sections.

- Economical and cost effective.

- Greater Flexibility: In industrial hose applications where high performance under harsh conditions is required, Titeflex UNI-BRAID® PTFE hose offers effective solutions and high value. The patented UNI-BRAID® construction features a single outer layer braid that reduces bulk while maximizing pressure capability and provides an exceptionally tight bend radius.

-65°F to 400°F (-54°C to 204°C)

Consult factory for temperature-adjusted pressure ratings.

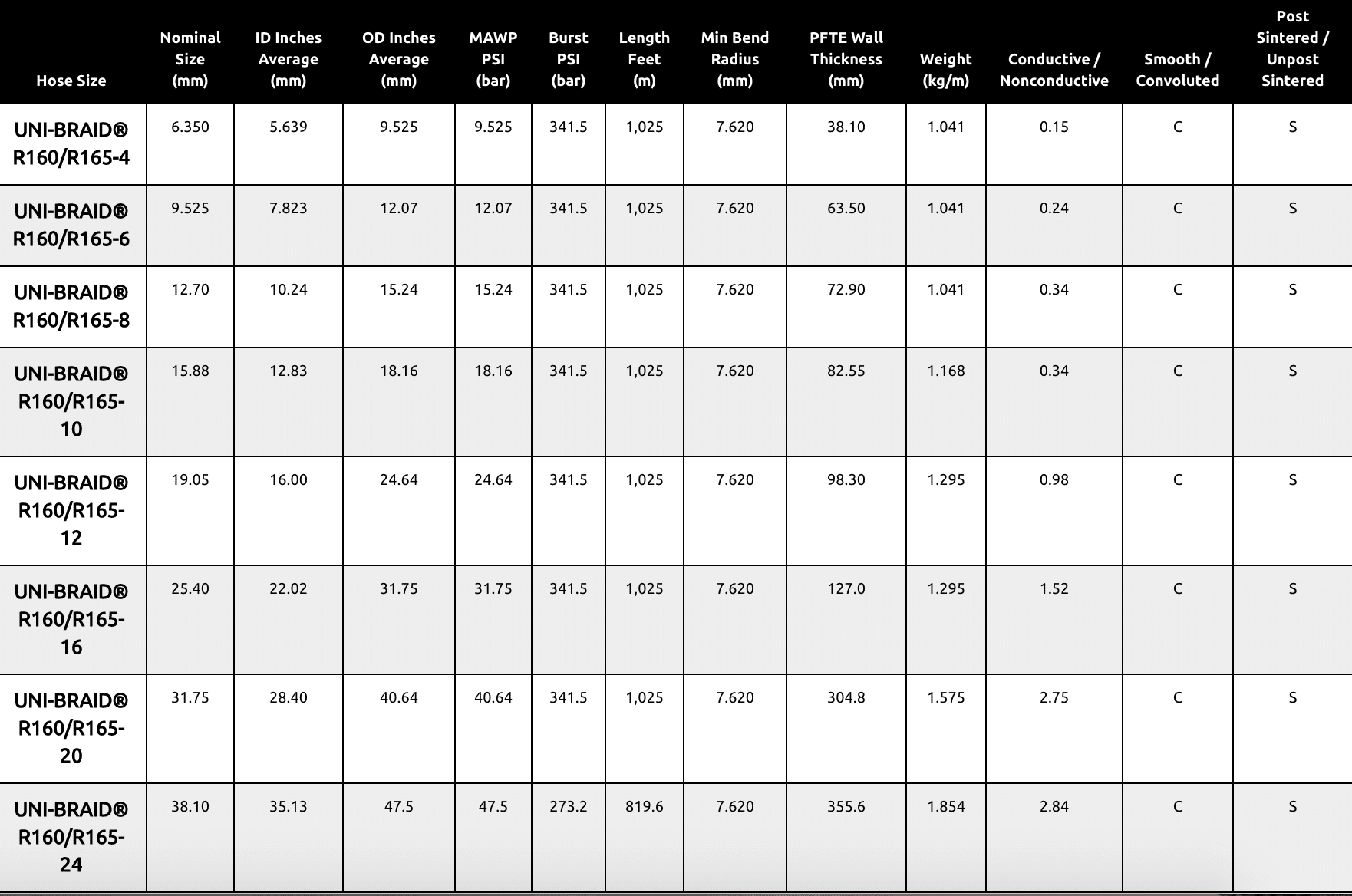

Imperial

Metric

DISCLAIMER: While every effort has been made to present the latest technically accurate information, industry standards and specifications are subject to revision at any time and human errors can occur. The products and designs offered herein, without limitation, are subject to change at any time without notice. Improper selection or use of products offered herein can result in injury or death.