Unmatched engineering and technical experience in the application of convoluted PTFE hose products has allowed users to consistently rely on Titeflex for dependable performance and value every time.

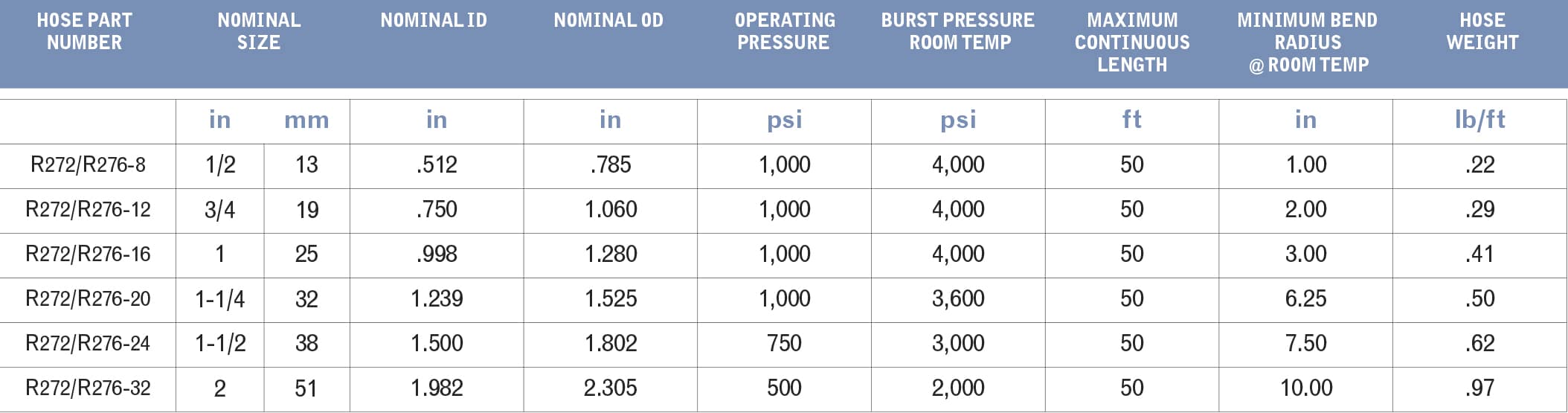

Titeflex R272/R276 Series

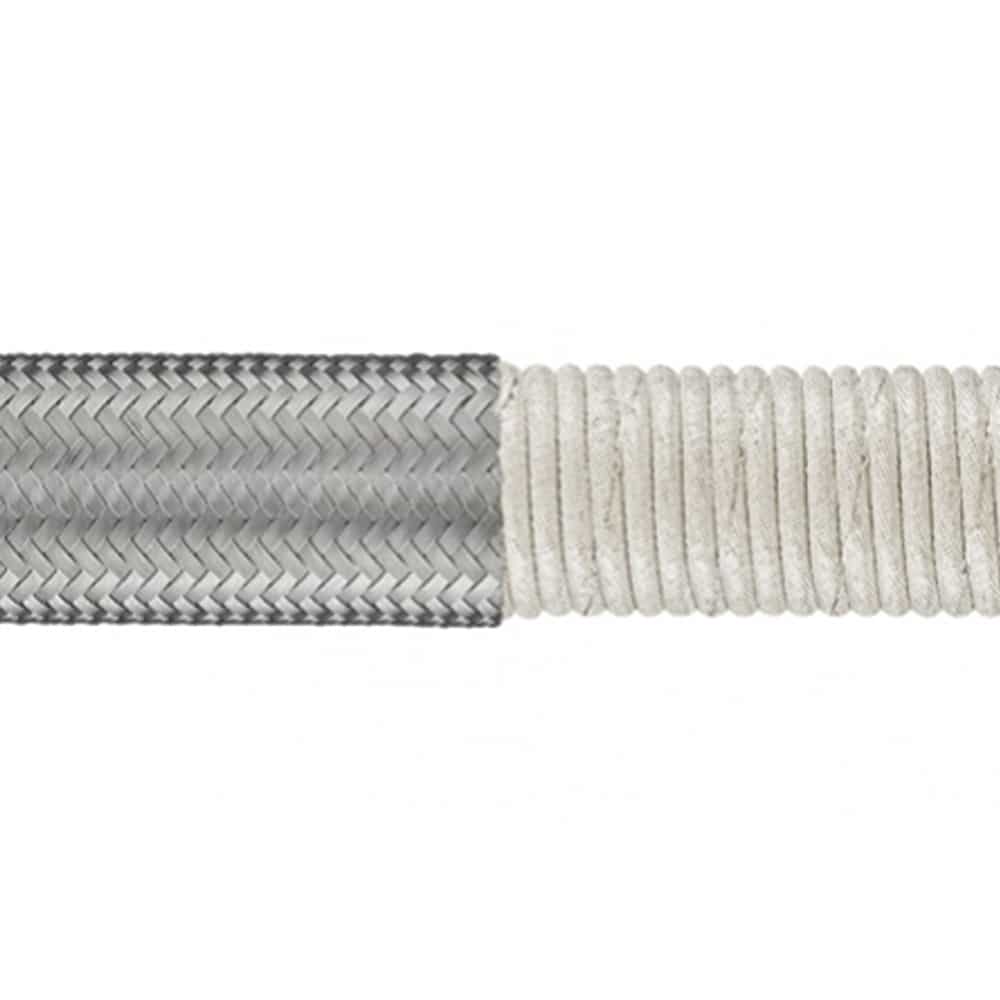

Hose Construction

A white non-conductive PTFE liner, externally reinforced with PTFE impregnated fiberglass and a single steel wire braid.

WARNING: This product can expose you to chemicals including Tetrafluoroethylene which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

- Chemical processing

- Pulp and paper

- Foam packaging

- Turbine engine componentry

- Air compressor discharge

- Tire press

- No Phthalate. Titeflex only uses 100% PTFE, and conductive PTFE in the liner that remains flexible and does not leach.

- Titeflex R272/R276 hose is extremely flexible and lightweight offering an improved alternative to maximize operator handling and safety in comparison to other types of industrial hose.

- Combined with PTFE’s unmatched chemical compatibility, corrosion resistance, temperature range and “non-stick” attributes, it offers a superior value.

- In addition, R276 offers a black conductive innercore for high flow rate transfer applications where elimination of static charges is required to ensure performance.

-40º F to 400º F (-40º to 204º C)

Consult factory for dynamic flexing applications at temperature limits and temperature adjusted pressure rating.

DISCLAIMER: While every effort has been made to present the latest technically accurate information, industry standards and specifications are subject to revision at any time and human errors can occur. The products and designs offered herein, without limitation, are subject to change at any time without notice. Improper selection or use of products offered herein can result in injury or death.