Polypropylene lined composite hose with high strength inner and outer wires providing conductive assemblies that allow for exceptional light weight handling with supreme flexibility and kink resistance available for vapor recovery and light fuel transfers yet engineered to withstand a hard vacuum.

A wide selection of end connections including aluminum flanges and couplers or steel/stainless steel flanges. Working pressures of up to 100 psi (7 bar) with conformance to EN 13765:2010 and temperatures of up to 100 C (212 F).

MarineMaster® Polypropylene Vapor Composite Hose Type 1321GGP and 3351PGP

This type is designed for use as a marine ship-to-shore or vessel-to-vessel vapor recovery hose suitable for large variety of hydrocarbon or chemical vapors.

Color/Cover: 1321GGP Yellow/2x PVC Coated Nylon, Abrasion and Ozone Resistant; 3351PGP Yellow Black Stripe/2x PVC Coated Nylon, Abrasion, and Ozone Resistant

Inner Wire: 1321GGP Galvanized Steel; 3351PGP Black Polypropylene coated steel

Inner Lining: High Grade Polypropylene

Carcass: Polypropylene Fabrics, Films and Polypropylene/Nylon Seamless Tubes

Outer Wire: Galvanized Steel

USCG Markings: Red/Yellow/Red ID Color each end, 2″ VAPOR logo and .625 pilot holes

Temperature Range: -22°F to +212°F (-30°C to +100°C)

Maximum Elongation: ≤10% on test pressure

Vacuum Range: 26 inHg (660 mmHg), 0.9 bar

Electrical Properties: Electrically Conductive; ≤1.0 ohm/m for size 2″

EN13765:2010, IMO, IBC, BS5842, USCG 33CFR 154.800 Vapor Line

Specially designed end fittings have been developed for use with Willcox Composite hoses that have a unique leak-proof sealing face and specially machined helical spiral shank which engages into the corresponding internal helix wire when secured into the hose by either crimping or swaging the external ferrules.

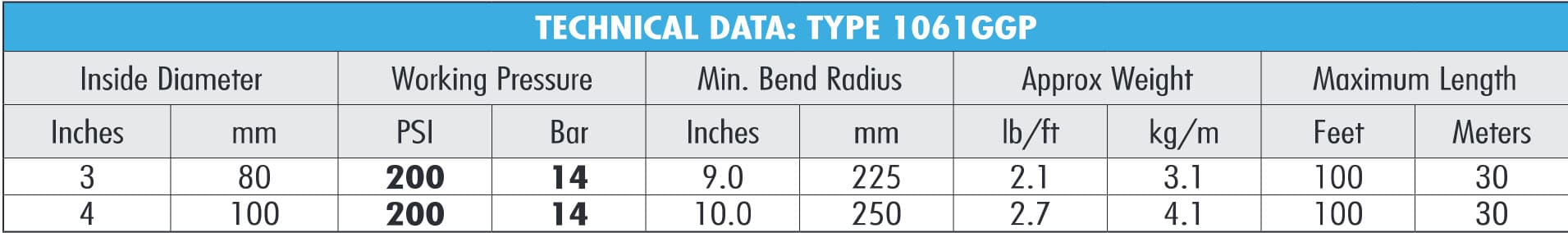

Pressure based on safety factor 4:1. Dimensions and weight are approximate and are subject to change. For additional technical data such as pressure drop, max. flow rates and tensile strength, please consult Titeflex US Hose engineering. Increased operating temperatures will reduce working pressure of the assemblies. Fitting pressure rating may limit working pressure of the assembly. Rated working pressure is @ 70°F (21°C).