Chlorine transfer is recognized as one of the most challenging and potentially hazardous hose applications.

Aware of the clear need for safety, reliability and performance, Titeflex has engineered a unique product to meet the demands of this critical application. Titeflex S818XX chlorine hoses are internationally accepted and recognized for providing many years of unparalleled safety and performance.

Chlorine/Bromine Hose

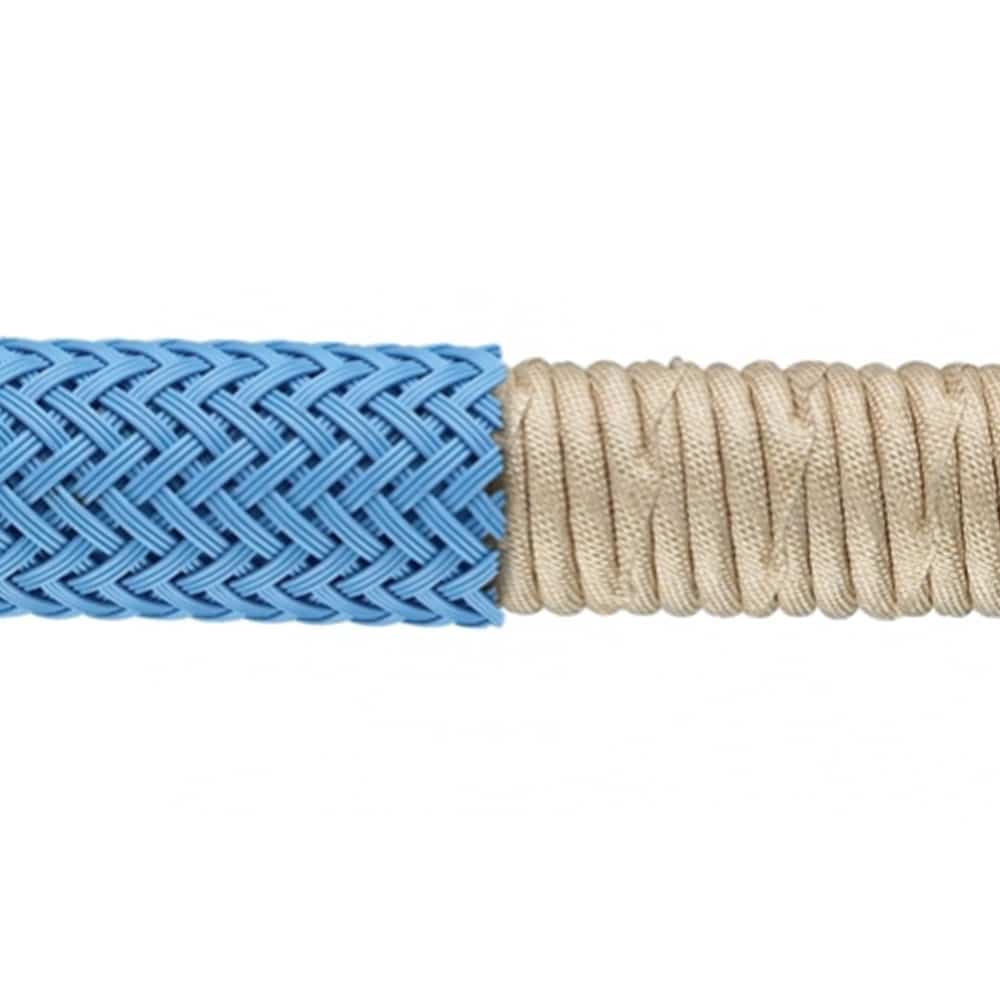

Hose Construction

- Convoluted PTFE core with a double layer of PVDF braid

- 1″ hoses are covered with a CPE jacket for abrasion protection

- Optional heavy duty high density polyethylene spiral wrap available

- Schedule 80 monel male pipe fittings

- Monel schedule MSS type A stub ends available for 1″ size

- 1/2″ size males have a press-fit liner/insert to prevent erosion

- S818XX hose’s innercore is thermally treated to enhance hose performance in extreme applications.

WARNING: This product can expose you to chemicals including Tetrafluoroethylene which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

- Size 1″ chlorine hose for rail car loading and unloading

- Titeflex 1/2″ chlorine hose for replacing copper whips at chlorine repackaging plants filling 1 ton containers and 100/150 lb. cylinders

- No Phthalate. Titeflex only uses 100% PTFE in the liner that remains flexible and does not leach.

- Engineered specifically to meet the critical application conditions of chlorine transfer

- Used worldwide by major chemical producers

- Meets or exceeds the Chlorine Institute guidelines, Pamphlet 6 Appendix A

- S818XX assemblies are more flexible and resilient than metal hose. The PTFE innercore is virtually stress-free in continuous flexing installations. The convolutions of Titeflex chlorine hose are shallow and helical, rather than annular as in metal hose, to facilitate draining and cleaning and reduce transfer time cycles.

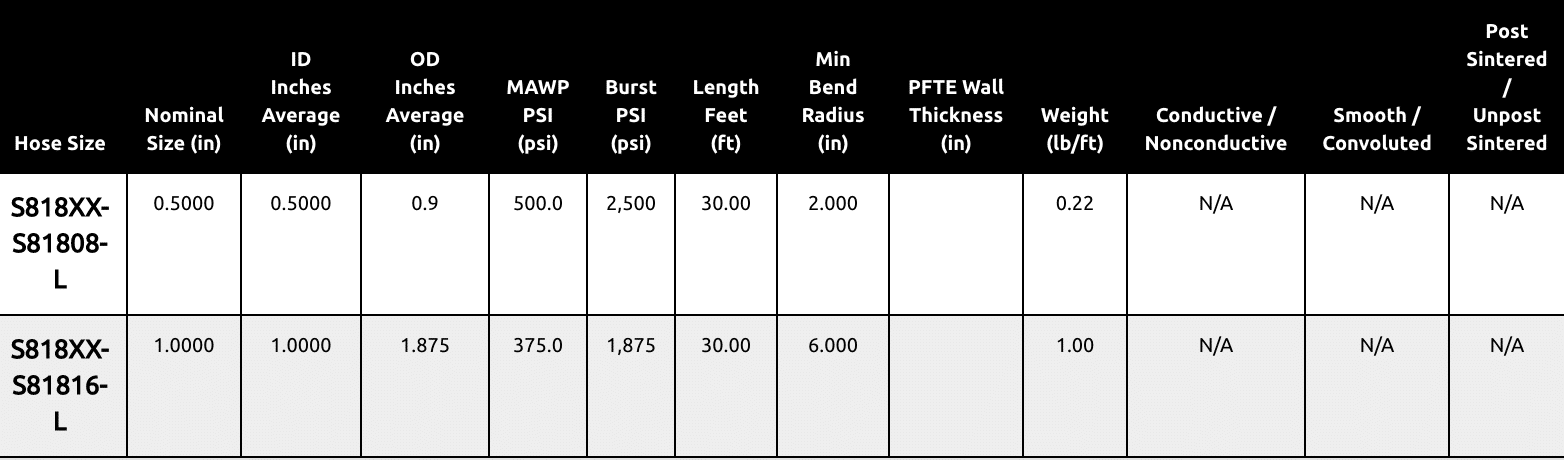

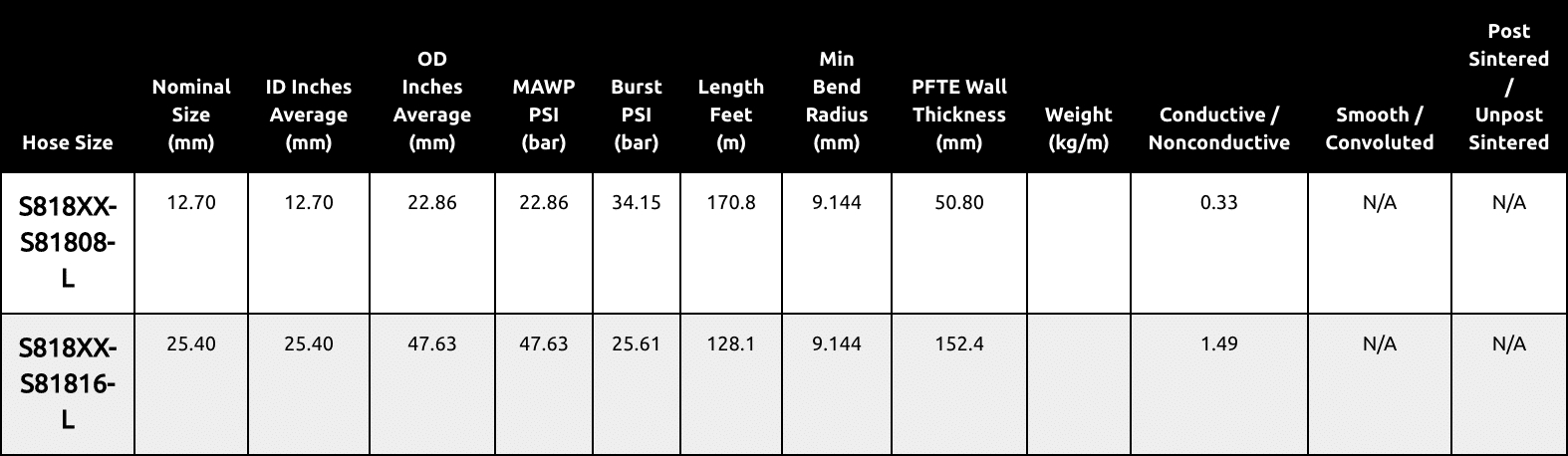

- Titeflex chlorine transfer hose is currently available in 1/2″ and 1″ ID’s. It offers full flow characteristics for faster loading and unloading and are supplied directly from the Titeflex plant in lengths from one to 30 feet.

- For quality assurance and traceability, each factory-made and tested assembly is serialized and recorded at Titeflex, along with the installation location and date. The assembly is also clearly tagged with its pressure and temperature ratings.

-40°F to 120°F (-40°C to 49°C)

Imperial

Metric

DISCLAIMER: While every effort has been made to present the latest technically accurate information, industry standards and specifications are subject to revision at any time and human errors can occur. The products and designs offered herein, without limitation, are subject to change at any time without notice. Improper selection or use of products offered herein can result in injury or death.