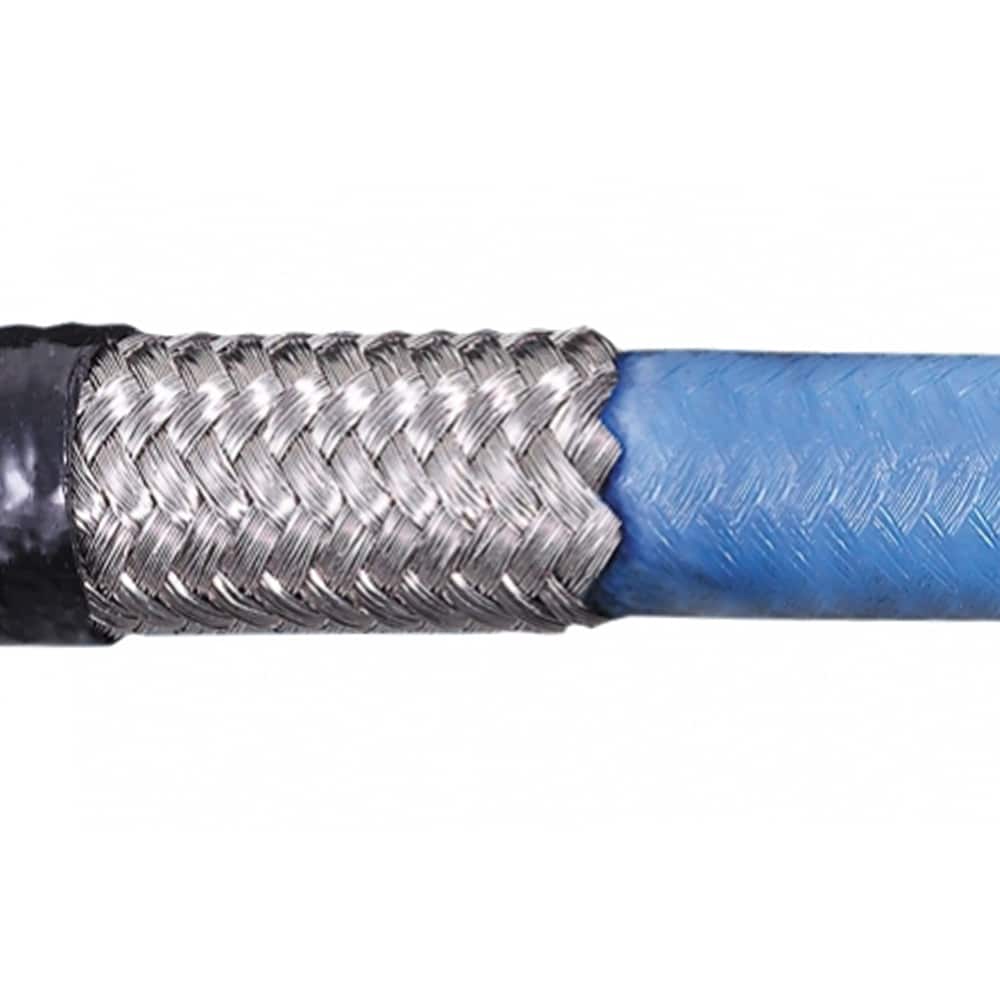

117198 hose has a nominal 0.040″ wall of conductive PTFE innercore and Uni-Braid® Stainless Steel braid wire reinforcement.

The PTFE and innercore is processed to improve the permeation resistance (compared to R122-series hose). The wire reinforcement consists of an innovative, patented, single braid wrap that improves performance without additional wire layers that add bulk and weight. An outer jacket of Hytrel® provides abrasion resistance and a labeling surface.

Titeflex 117198 Series

-65°F to +450°F (-54°C to +232°C)

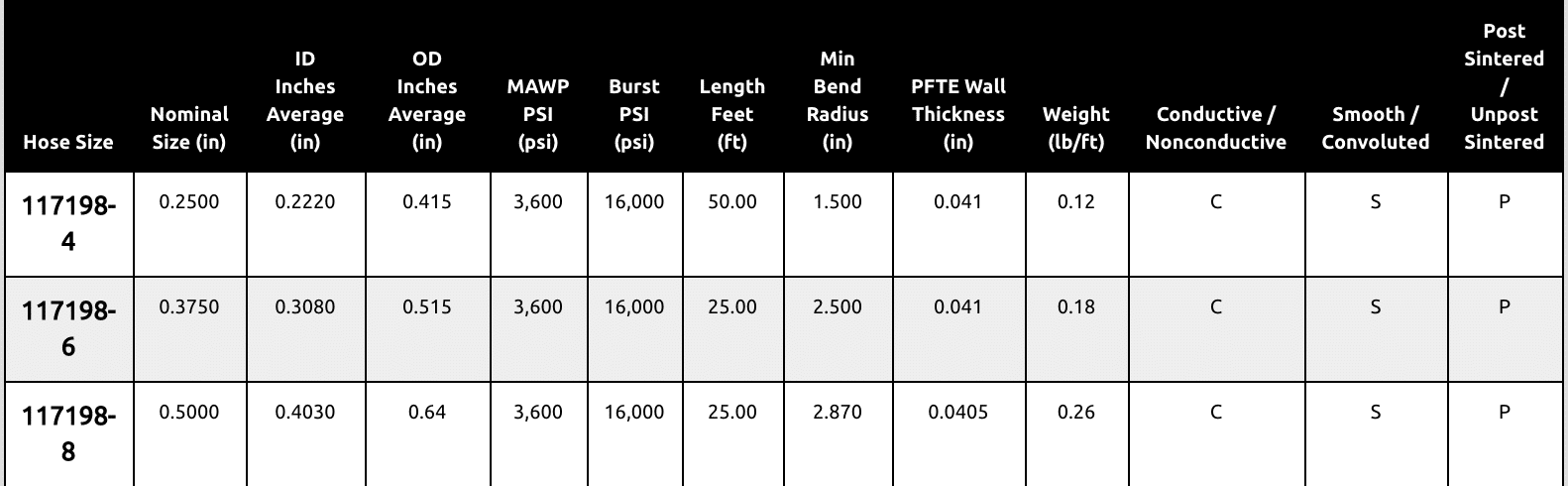

Imperial

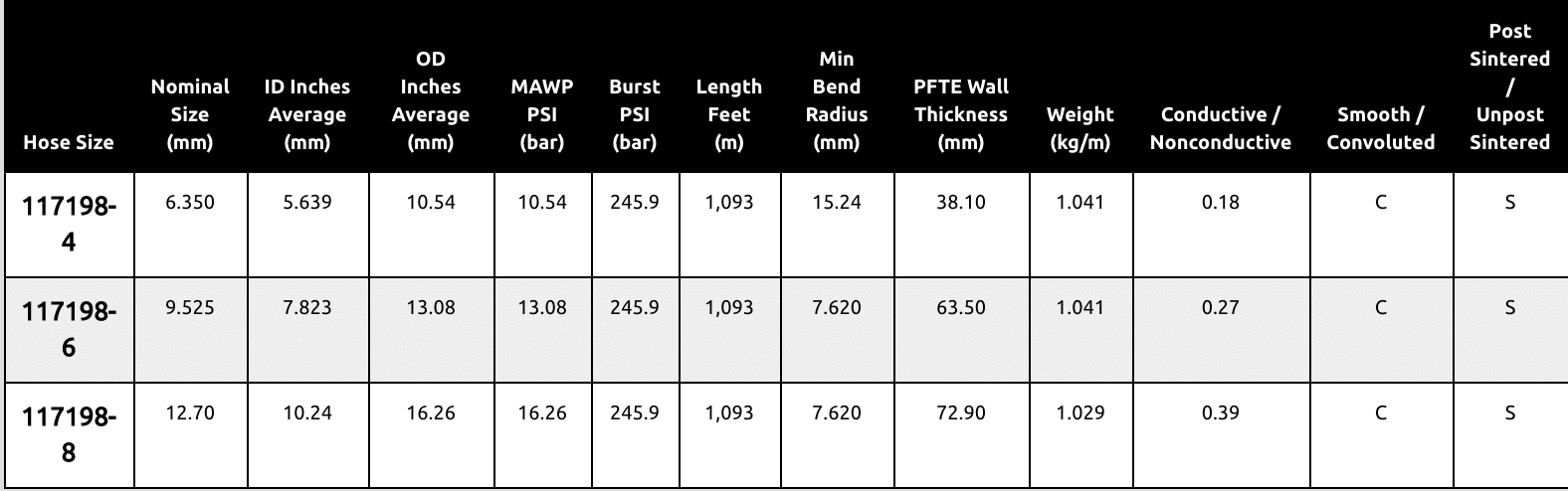

Metric

DISCLAIMER: While every effort has been made to present the latest technically accurate information, industry standards and specifications are subject to revision at any time and human errors can occur. The products and designs offered herein, without limitation, are subject to change at any time without notice. Improper selection or use of products offered herein can result in injury or death.

ETPV thermoplastic elastomer can be applied as an integral sleeve, providing complete corrosion protection, abraison resistance, and a labeling surface for most automotive applications. ETPV sleeving can be “crimped over” reducing skiving and improving sound attenuation. The EPTV sleeving can also aid in preforming of the hose. Additional thermoplastic sleeves, such as Sarlink® and Hytrel® are also available for abrasion protection and labeling of the hose.

Hytrel® is a registered trademark of DuPont.

Sarlink® is a registered trademark of DSM.