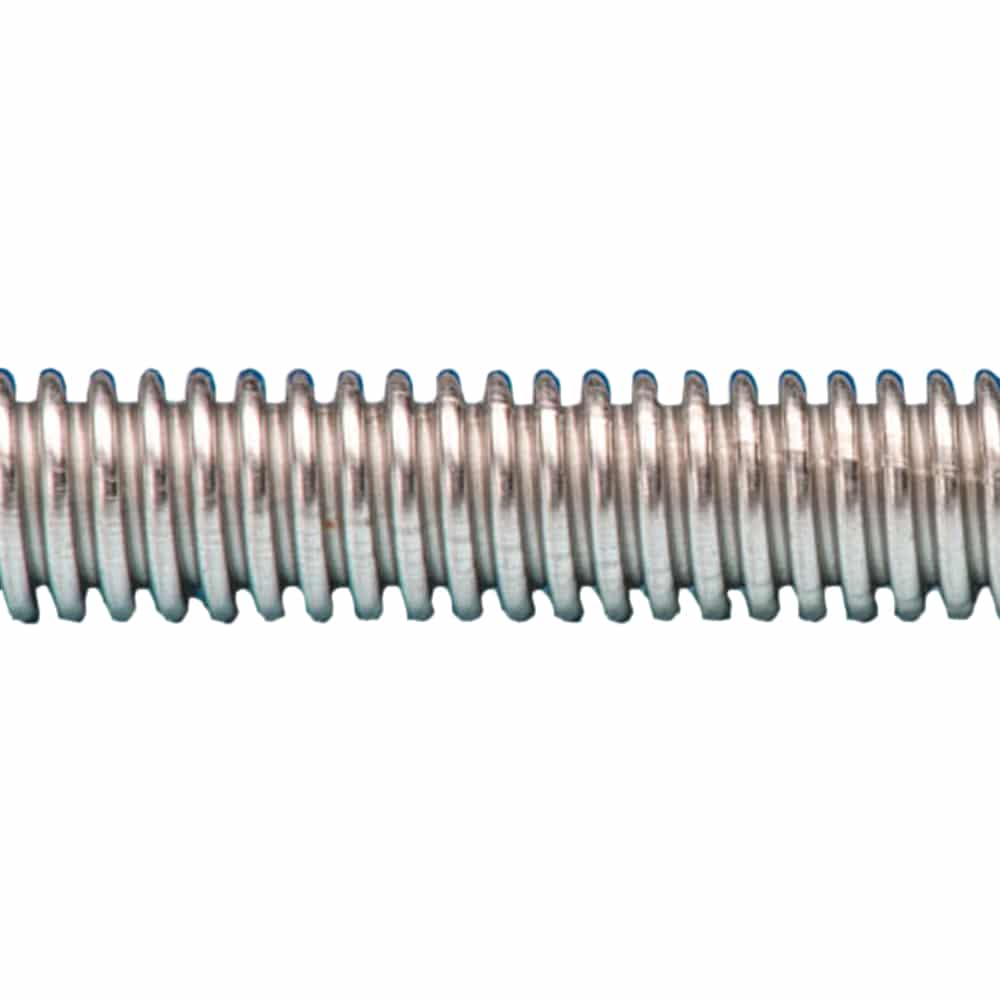

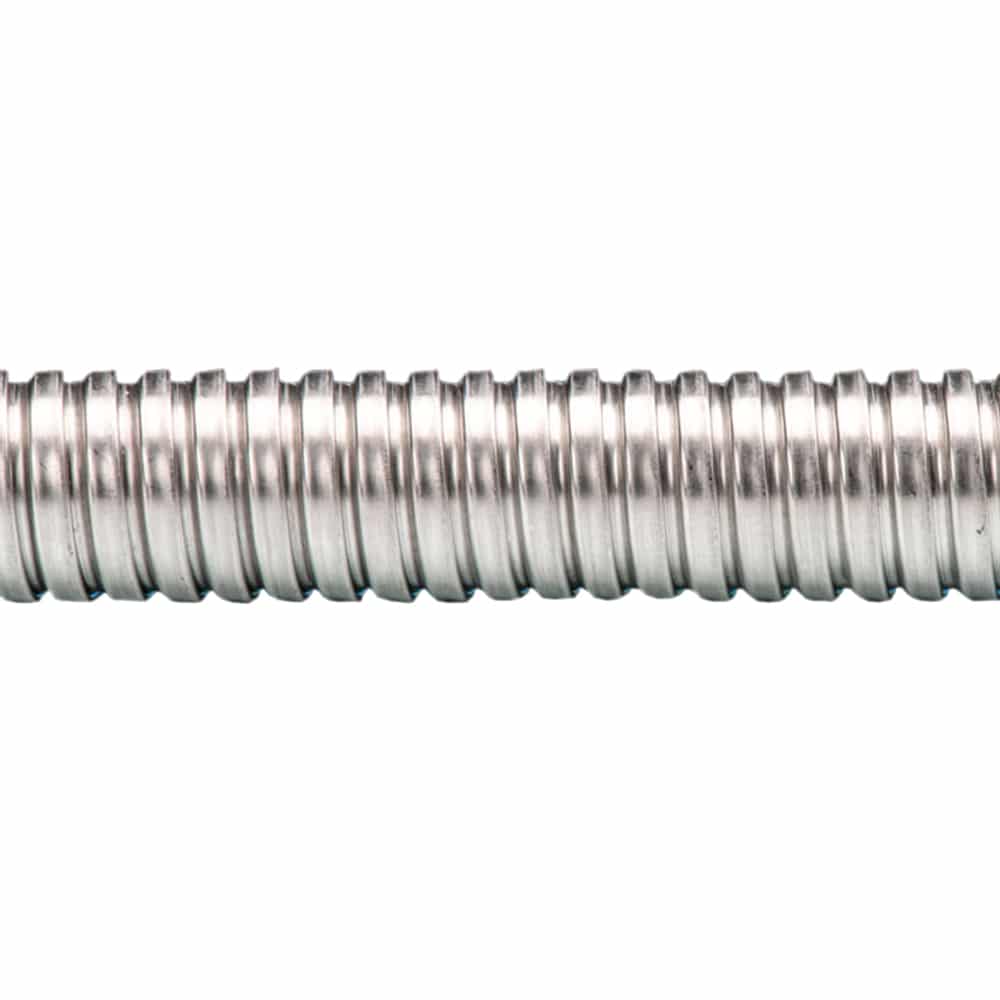

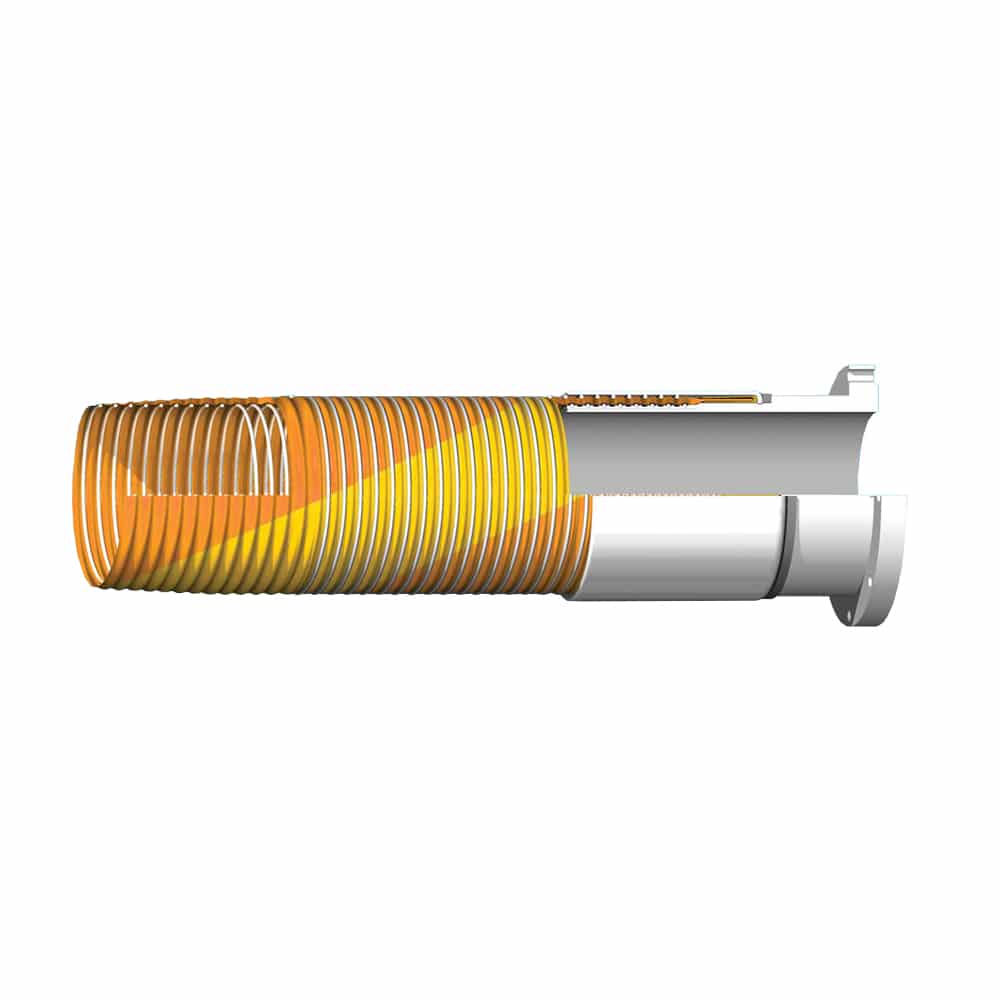

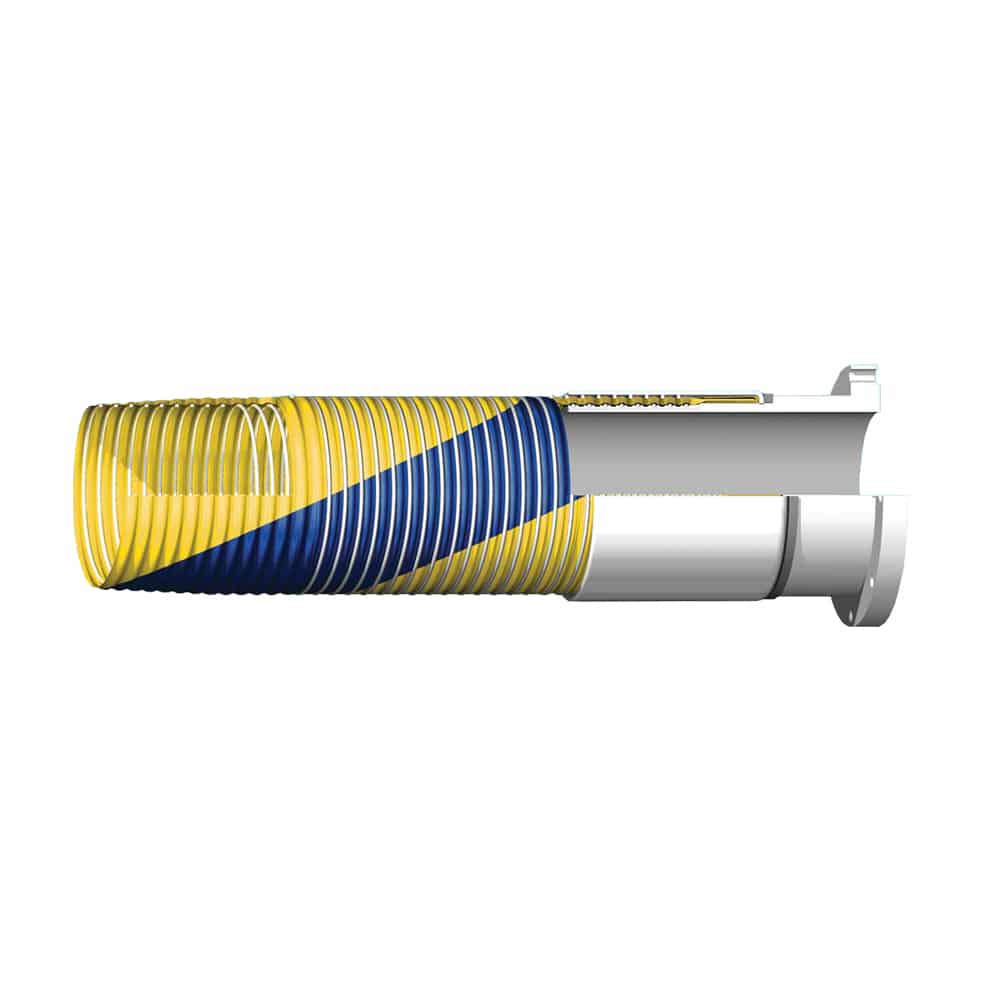

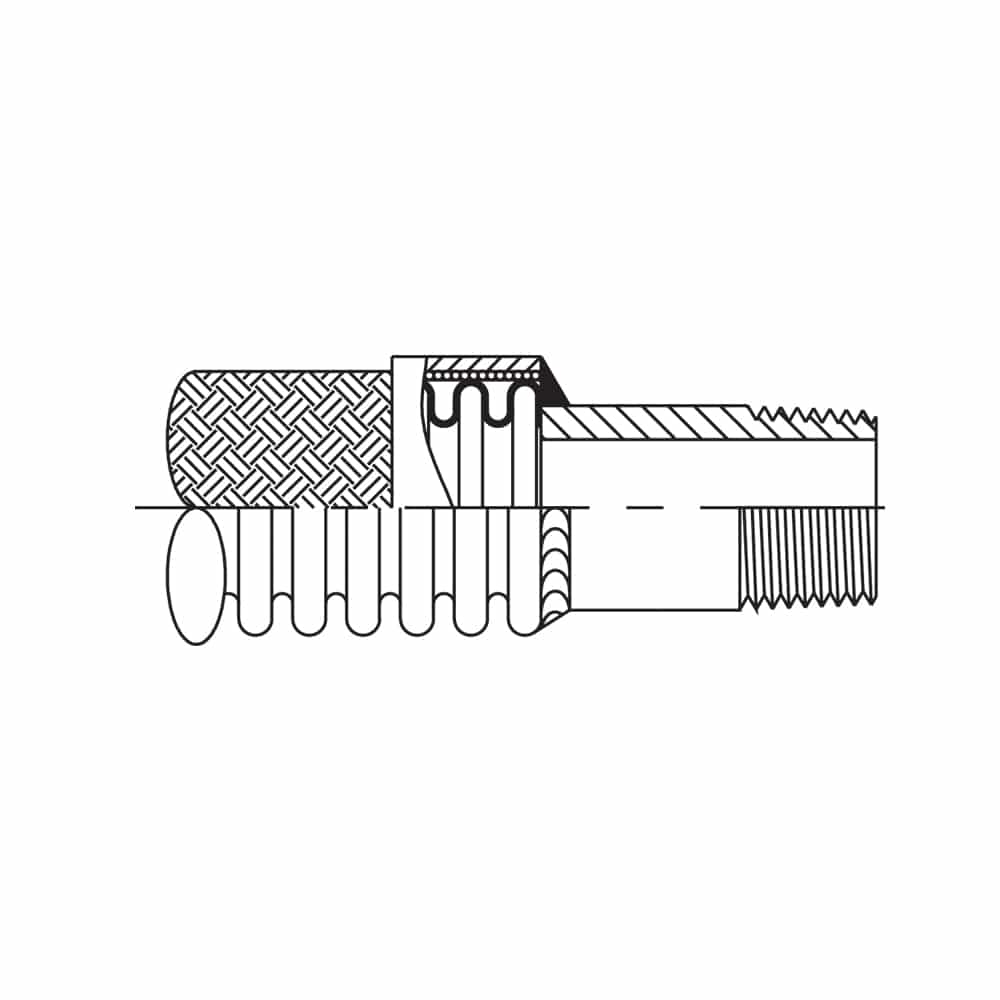

Titeflex US Hose provides solutions for up and downstream operations, including: composite hose assemblies (ship-to-shore / ship-to-ship hydrocarbon, chemical and cryogenic transfers); LPG and LNG hose assemblies; large diameter insulated metallic hose assemblies (LPG / LNG for FPSO’s, shuttle tankers, and regasification facilities); large diameter metallic hose (tank settlement joints and connections); and high-pressure metallic hoses, up to 3,000 psi in 3” diameter (natural gas operations).

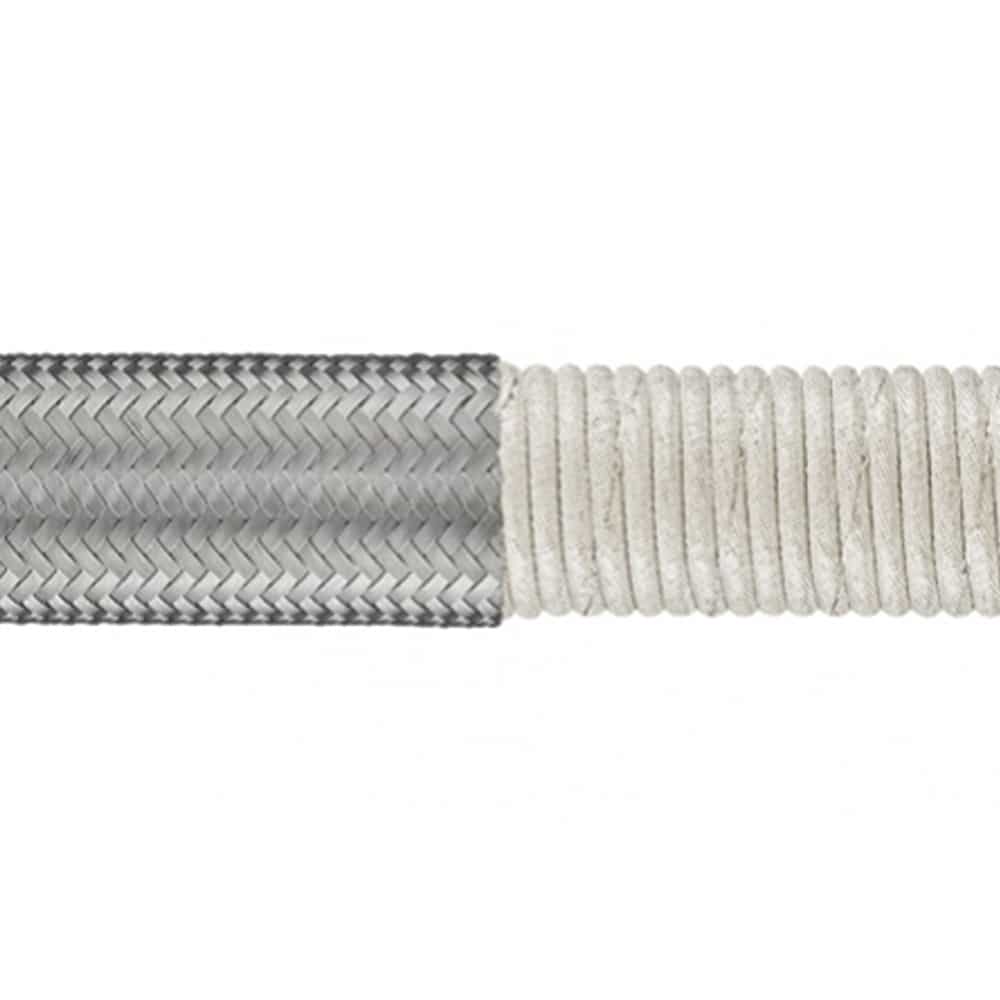

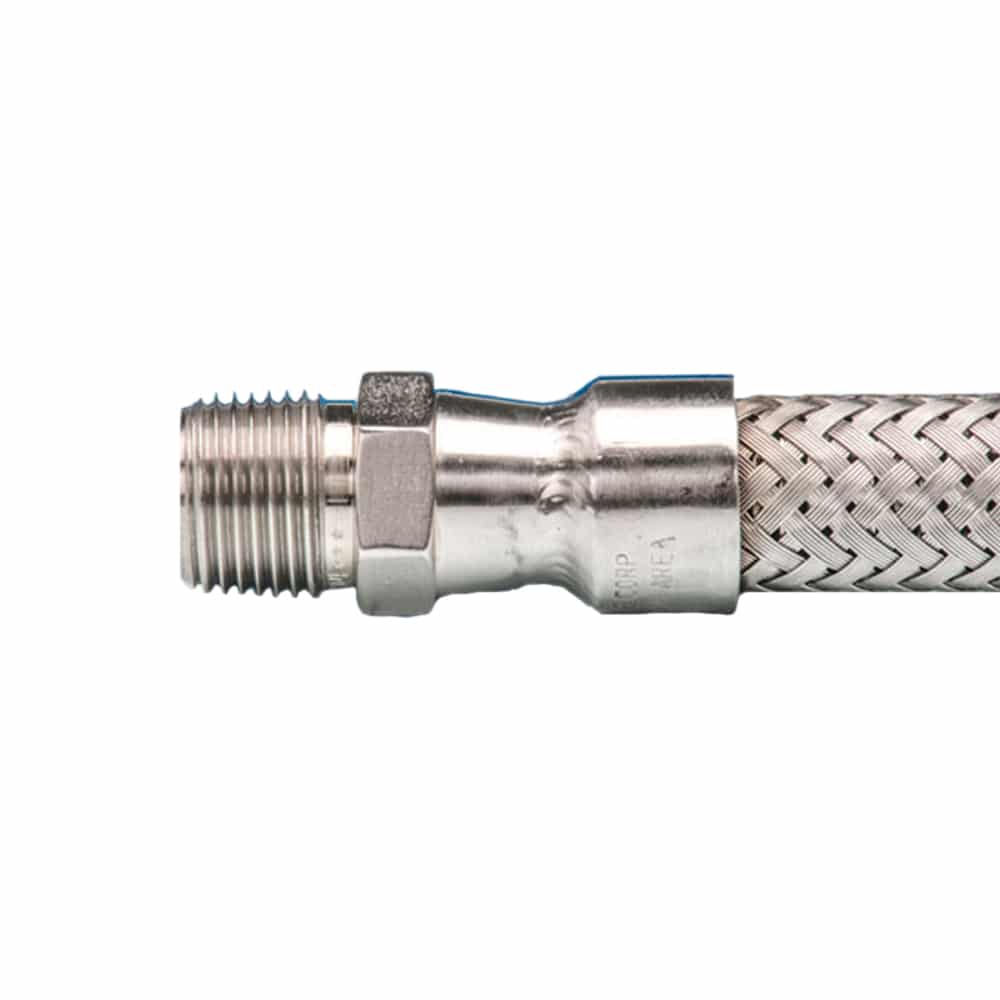

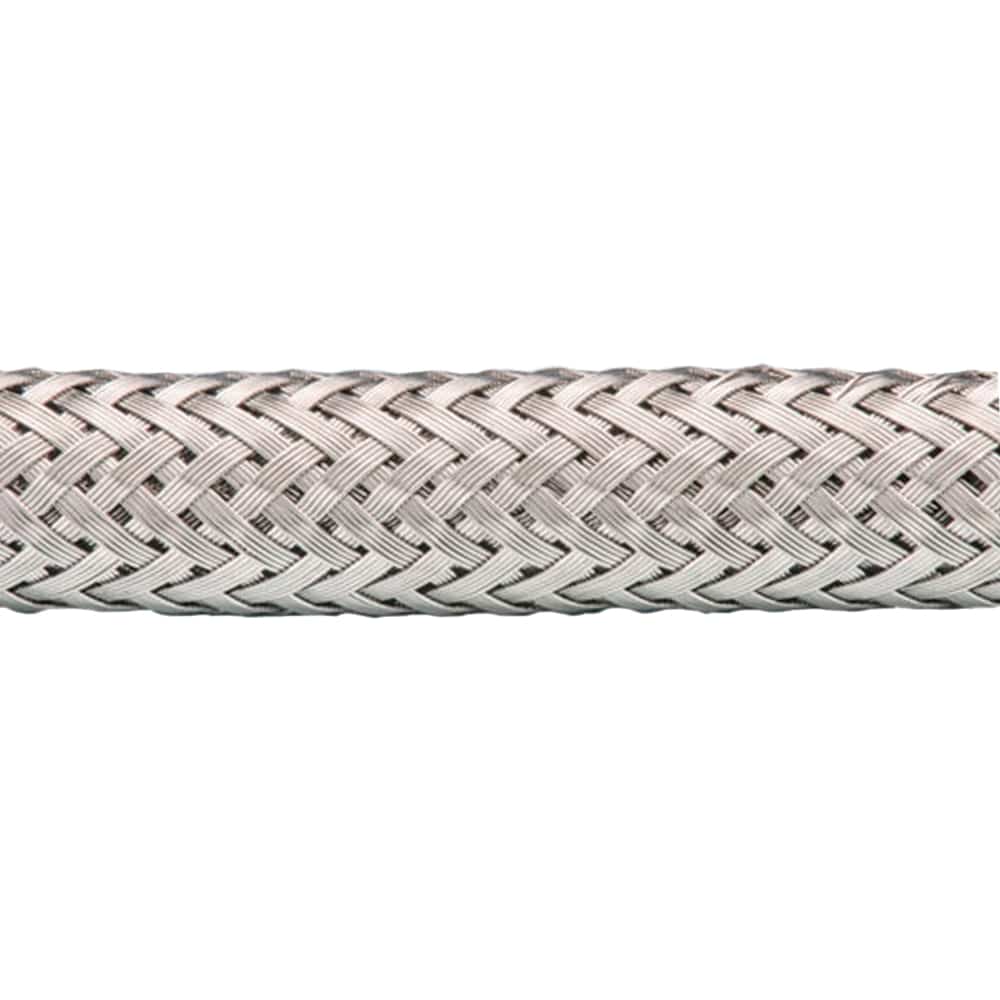

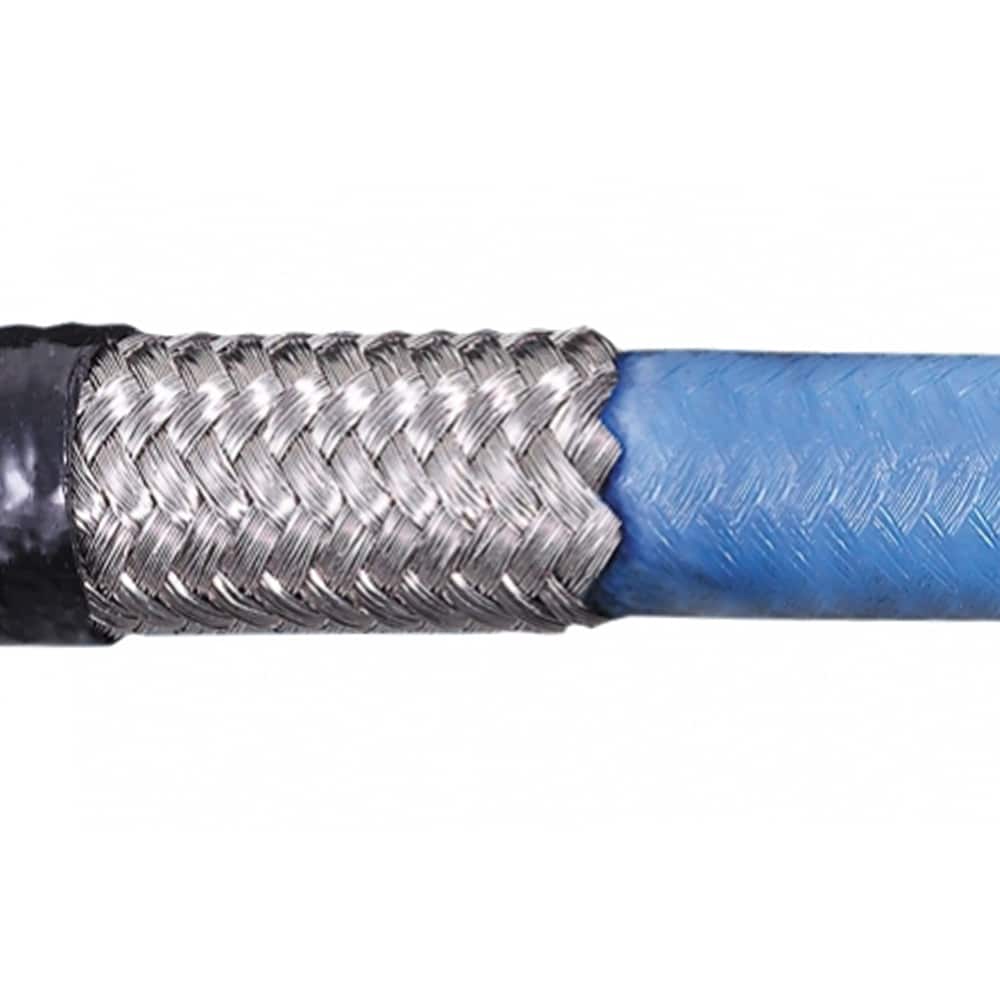

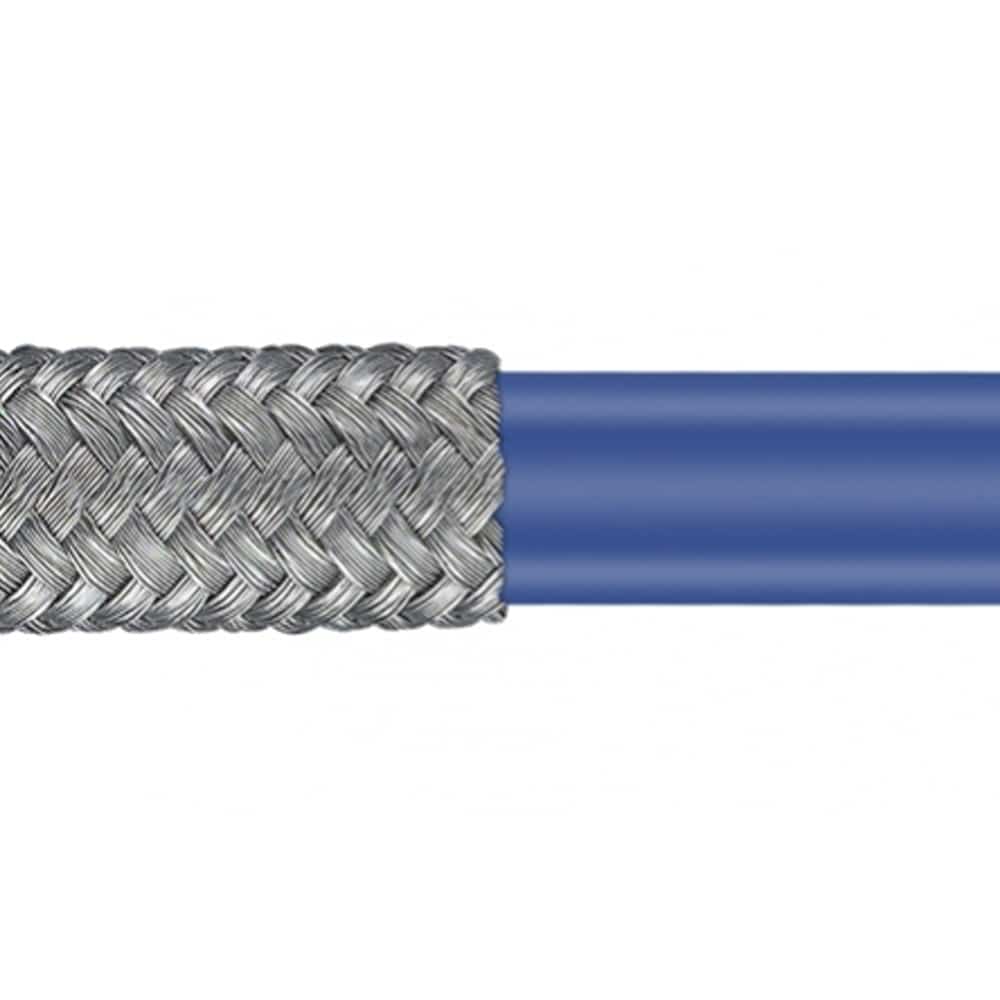

We provide flexible connectors on pumps and generators that eliminate vibration to pipework, braided hose assemblies resistant to high temperature (such as Inconel 625 braided hose assemblies as flexible flare pipes), submersible composite hose assemblies resistant to chemicals, and hoses resistant to seawater and saline environments (including Monel 400 and Hastelloy C-276). Replacing rubber hoses with fire resistant high-pressure metallic hose can drastically improve reliability in your application.

Note: All metallic assemblies are assembled by ASME Section IX certified welders with available WPS/PQR’s for client examination. Vigorously tested to appropriate standards, including hydrostatical tests, dye penetrant tests, radiographic interpretation, and/or high pressure nitrogen/helium testing.