High pressure smooth bore anti-static PTFE hose with Dense-Pac braid reinforcement supports high pressure operation in a lightweight flexible construction.

Can be used in higher temperature service conditions such as high temperature hydraulics (phosphate-ester based) in steel mills, plastics reaction injection molding (RIM), heated hose dispensing hot-melts and high pressure gas and oxygen transfer. Available sintered for gas, non-sintered for liquids, in single or double braid.

Heavy Wall PTFE fully Anti-static innercore to eliminate potential dangerous build-up of static charges (see Technical Bulletin). FDA compliant. PTFE compliant with ISO 12086 Part 1. Dense-Pac assemblies are manufactured with either a post-sintered PTFE core for gas and pneumatic service or a non post-sintered PTFE innercore for transferring liquids which provides lower cost without sacrificing performance.

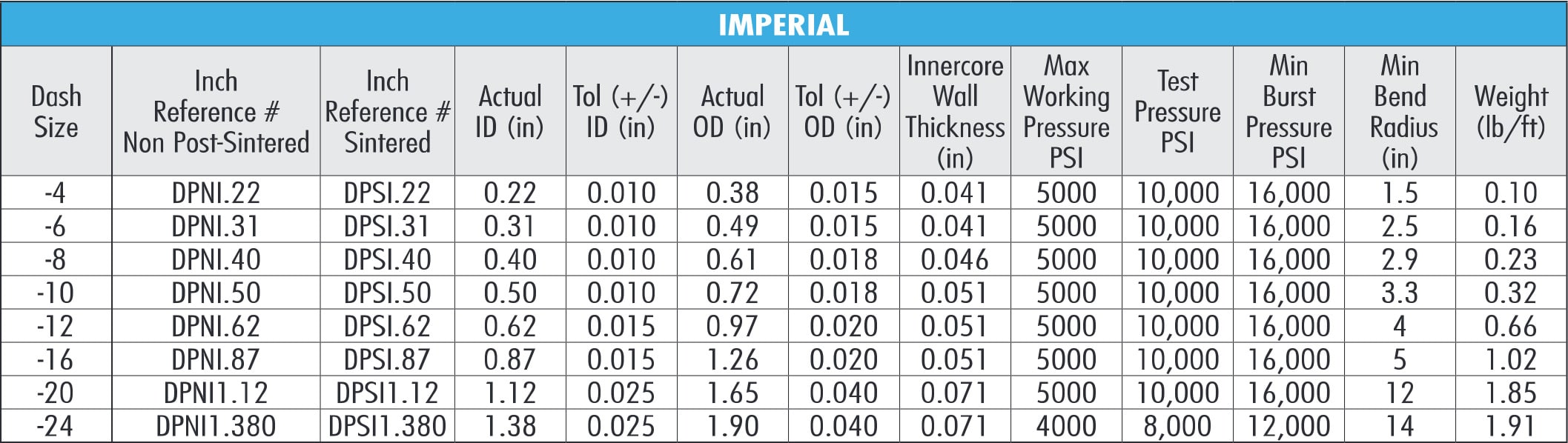

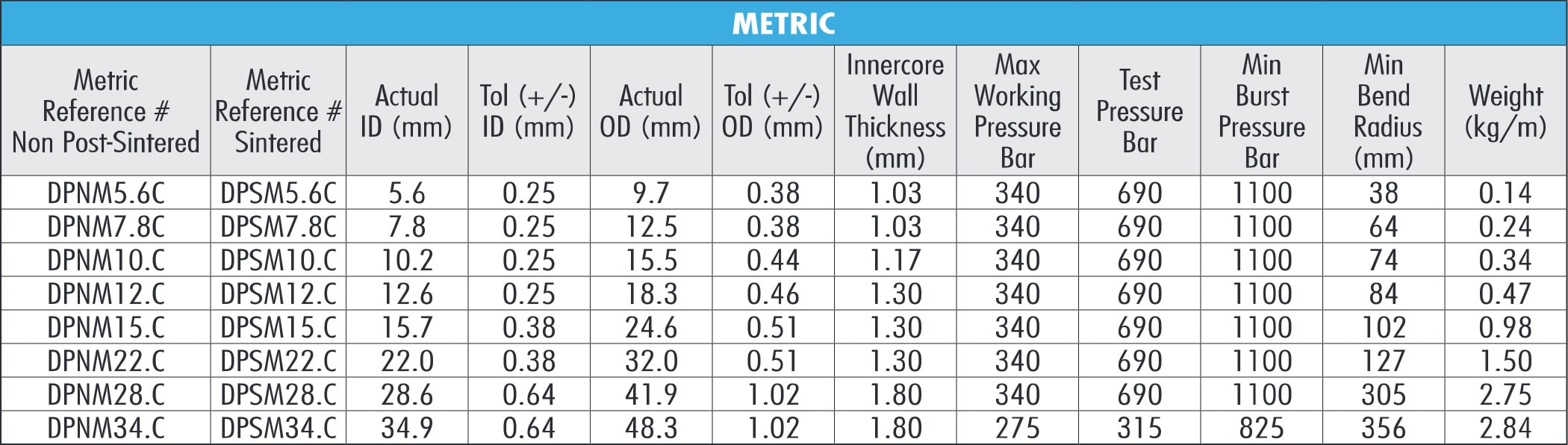

Exterior braid is constructed with multiple wires twisted together to form a lighter-weight more flexible high pressure hose. Sizes .22 (5.6mm) to .50 (12.6mm) ID have a single layer of type 304 stainless steel high tensile wire EN 1.4301 and sizes .62 (15.7mm) to 1.38 (34.9mm) have two layers of braid.

-65°F (-54°C) to +500°F (+260°C)

Female JICs in type 300 series stainless steel

*Minimum burst pressure calculated at 70°F (21°C). Non-impulse applications. For impulse applications, working pressure is 3000 PSI (207 Bar). High temperature pressures calculated at 400°F (205°C): working pressure drops to 3000 PSI (207 Bar). Please contact the factory. For gas and air applications specify DP post-sintered only.