Our rubber covered hose has been custom engineered for lasting service in critical transfer applications.

We can produce assemblies to your specific length and diameter needs to connect to your system. If you do not find the exact hose and fitting combination required for your service please contact our Customer Service. You can be assured our Engineering experts will be easy to talk to and focused on solving your problem.

Rubber Covered FEP Hose • Jack-Chem

Chemical, Pharmaceutical and Food Processing

Starts with a chemically inert smooth HP liner that is FDA compliant. The FEP liner is made to last with a heavy wall construction that provides more hoop strength and resistance to kinking during flexing.

Multiple plies of synthetic EPDM rubber are reinforced with a horizontal fabric braid, the inner layer of synthetic rubber is permanently bonded to the exterior of the FEP innercore. A wire helix is included to support the shape in full vacuum service and to further prevent kinking.

-65°F (-54°C) to +300°F (148°C) For temperatures over +300°F (148°C) contact the factory.

Complete range stainless steel couplings in type 316SS also PFA encapsulated fittings for extreme corrosion resistance throughout entire wetted flow path.

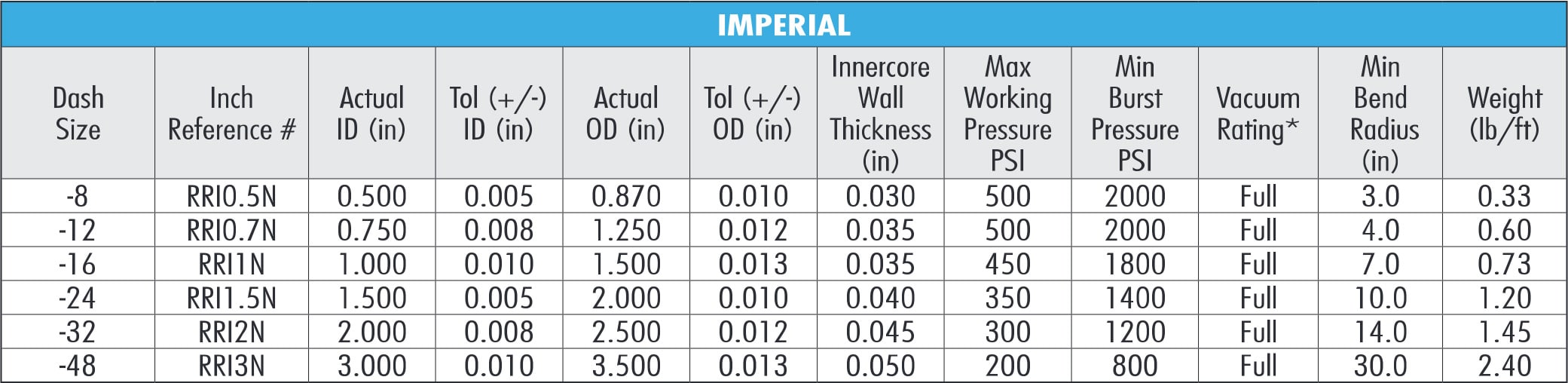

All pressure and vacuum ranges are calculated at 70°F (21°C).