Extra High Pressure smooth bore PFA or ETFE core (FDA compliant) with aramid fiber and 304SS wire over-braid, outer cover of abrasion resistant Hytrel color coded blue for ETFE and black for PFA innercore.

Ultra is lightweight yet offers high working pressures for inert gas applications and various liquids. Examples applications include compressed gas cylinder filling, spray dryers in milk powder productions, and replacement of rigid high pressure stainless steel tubing in the aerospace industry. Ability to couple 150 plus continuous lengths with no splice joints.

Ultra is ideal for inert gas applications and liquids requiring FDA compliance. Examples of applications included compressed gas cylinder filling, spray dryers in milk powder production and replacement of rigid high pressure stainless steel tubing or corrugated metal hose in long lengths. We are able to couple up to 150 feet (46m) continuous lengths with no splices.

Fluoropolymer innercores of non-conductive ETH or PFA that are fully FDA compliant. PFA and ETFE innercores for gas and pneumatic service; these Fluoropolymers unlike PTFE do not require any post sintering.

Ultra incorporates the use of one braided layer of high tensile aramid fiber and one layer of stainless steel. This value engineered construction reduces weight and improves bend radius while increasing burst pressure. An integral abrasion resistant Hytrel jacket protects the exterior braid and has a smooth finished appearance.

- Without Hytrel Cover -65°F (54°C) to +500°F (260°C)

- With Hytrel Cover -20°F (-29°C) to +180°F (82°C)

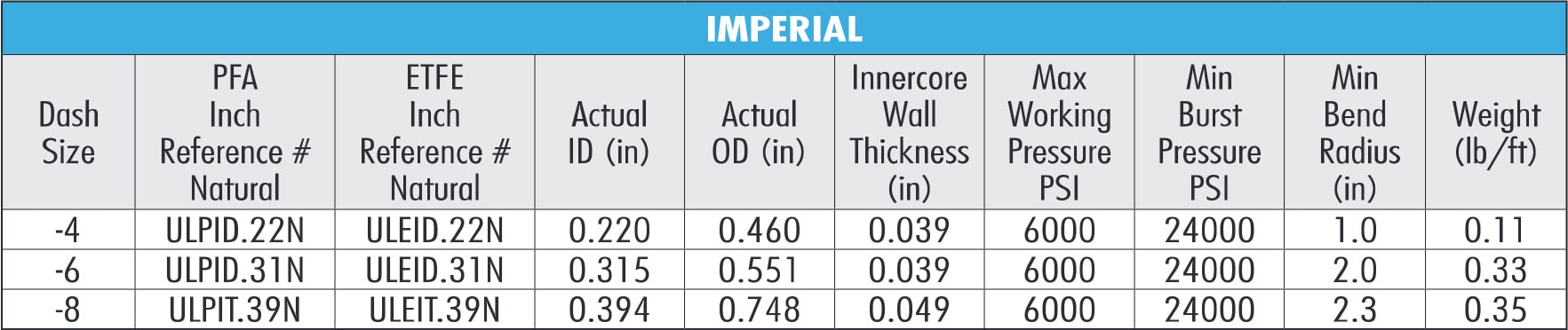

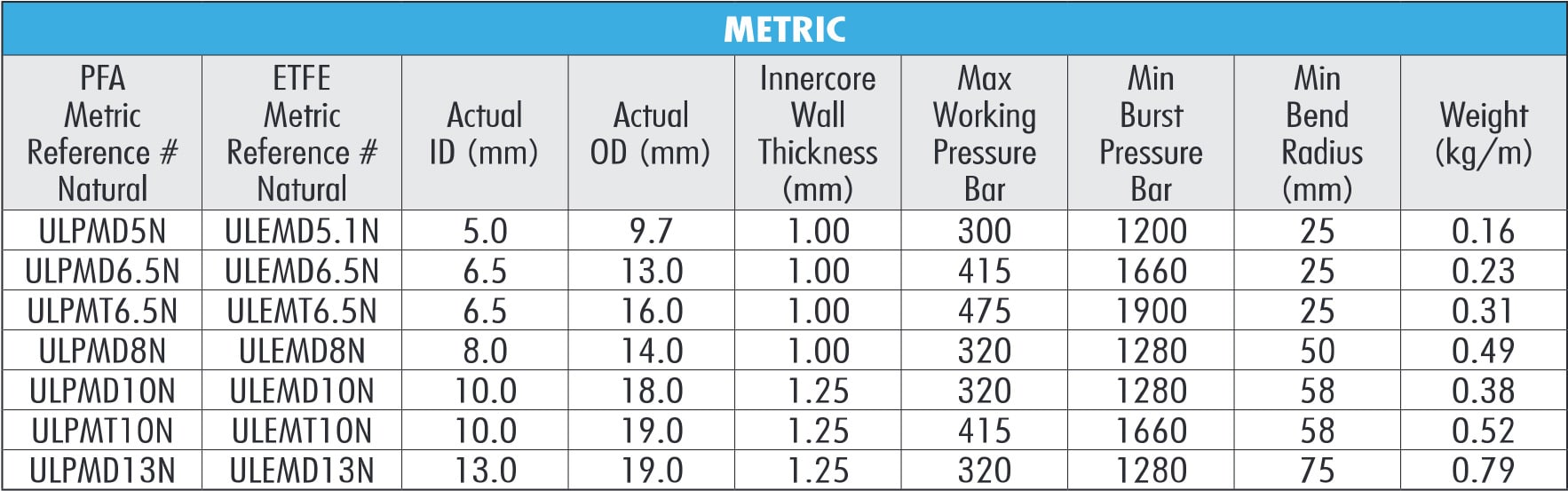

Minimum burst pressures are based on 70°F (21 °C). For high temperatures please consult the factory.