MTLC hose is engineered with a smooth PTFE innercore which is inserted and locked in place in reinforced corrugated metal hose that is also manufactured by Titeflex US Hose.

The PTFE liner is flared over each end so that the entire wetted flow path is in contact with PTFE Fluoropolymer. This is a heavy duty containment hose. Vent holes in the metal assembly prevents gas build up between the PTFE liner and metal hose. We can produce assemblies to your specific length and diameter needs to connect to your system. You can be assured our Engineering experts will be easy to talk to and focused on solving your problem.

MTLC Hose

Chemical processing industry to aid in eliminating vibration and slight misalignment in lined pipe systems.

MTLC starts with a chemically inert smooth PTFE liner that is FDA compliant. The PTFE liner is made to last with a heavy wall construction.

Heavy wall 321 stainless steel corrugated metal hose outer assembly with one layer of 300 series stainless steel braid reinforcement.

-65°F (-54°C) to +500°F (+260°C)

PTFE flare over stainless steel flange retainer with your choice of backing flange. Backing flanges can be provided to meet various standards. Typical flange alloys are carbon steel, 304 and 316 stainless steel.

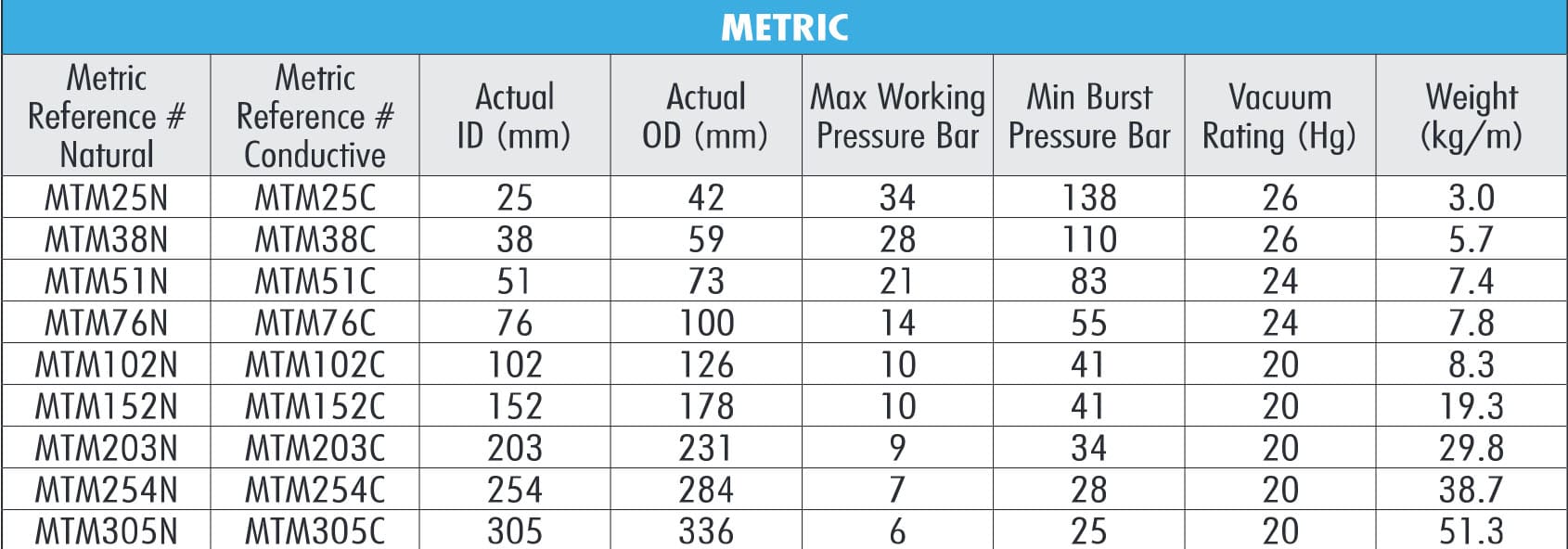

All pressure and vacuum ratings are calculated at 70°F (21°C). Note MTLC assemblies have limited flexibility and are not intended to be used in dynamic constant flexing service.