Smooth bore anti-static PTFE innercore with multiple layers of high tensile 304 stainless steel braid reinforcement.

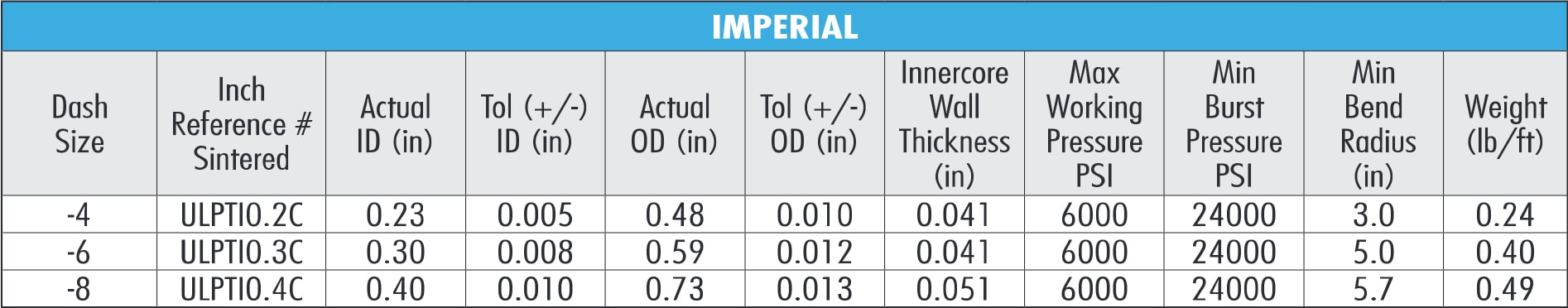

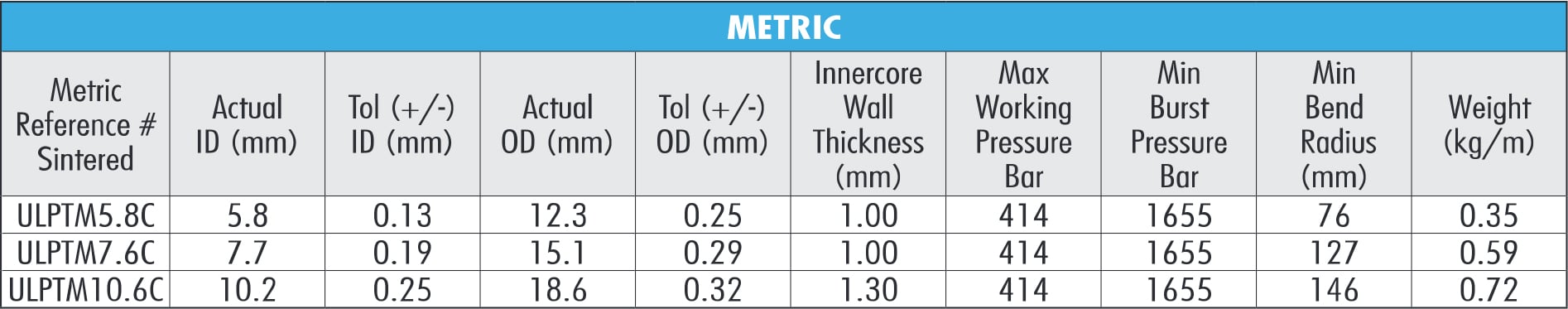

Increases service life and is ideal for high temperature and high pressure impulse service conditions. Applications include hydraulics, pneumatics, heated hose, high pressure gas and oxygen transfer as well as various liquids and chemicals. Minimum burst pressure of 24,000 PSI. Maximum working pressure of 6,000 PSI. Previously known as 58-series.

Multi-Braid Extra High Pressure Hose

Multi-Braid High Pressure PTFE hose is ideal for chemicals, hydraulic fluids, epoxies, sealants, adhesives and compressed gases. We can produce assemblies to your specific length and diameter needs to connect to your system. If you do not find the exact hose and fitting combination required for your service, please contact our customer service. You can be assured our engineering experts will be easy to talk to and focused on solving your problem.

Multi-Braid Series excels at in high temperature and high impulsive service conditions. High temperature or extreme impulse hydraulics, plastics reaction injection molding (RIM), heated hose, high pressure gas and oxygen transfer, liquids and chemicals.

Heavy Wall PTFE fully Anti-static innercore to eliminate potential dangerous build-up of static charges (see Technical Bulletin). FDA compliant. PTFE compliant with ISO 12086 Part 1. Multi-Braid series assemblies are manufactured with a post-sintered PTFE core for gas and pneumatic service to minimize effusion.

Exterior braid is constructed with multiple layers of altering spiral wrap and braid of type 304 stainless steel high tensile wire EN 1.4301.

-65°F (-54°C) to +500°F (+260°C)

Female JICs in type 300 series stainless steel. Fixed 1/4″ female NPT and 1/4″ male NPT available for -4 size.

Minimum burst pressures are based on 70°F (21°C). For high temperatures please consult the factory.